Bread Cutting and Injecting Machine

In the ever-evolving world of food processing and bakery equipment, the integration of innovative technologies has significantly enhanced productivity, precision, and overall product quality. Among these advancements, the Bread Cutting and Injecting Machine equipped with ultrasonic technology stands out as a game-changer, particularly in the realm of bread production. This article delves into the intricacies of this innovative machine, focusing on its ultrasonic cutting capabilities and how it seamlessly integrates with cream filling functions to revolutionize the baking industry.

Introduction

Bread, a staple in countless diets worldwide, has seen a remarkable transformation in its production processes over the years. From traditional hand-crafted methods to modern, automated systems, every innovation has aimed to improve efficiency, consistency, and taste. The introduction of the Bread Cutting and Injecting Machine, particularly with its ultrasonic cutting technology, represents a significant leap forward in the pursuit of perfection.

Understanding Ultrasonic Cutting Technology

Ultrasonic cutting technology leverages high-frequency vibrations to achieve precise and smooth cuts without the need for traditional blades. The nano-scale vibrations generated by the machine’s ultrasonic transducer enable it to cut through materials with minimal force and minimal disruption to their internal structure. In the context of bread production, this technology offers several distinct advantages over conventional mechanical cutting methods.

Advantages of Ultrasonic Cutting

Precision and Smoothness: The vibrations create a micro-sawing effect that results in incredibly fine and smooth cuts. This ensures that bread slices maintain their integrity and structure, with minimal crushing or deformation.

Preservation of Nutrients: Since ultrasonic cutting requires minimal force, it helps preserve the nutrients, moisture, and texture of the bread, enhancing its overall quality and appeal.

Reduced Waste: The precise cutting minimizes the amount of unusable bread crumbs or uneven slices, thereby reducing waste and increasing yield.

Efficiency and Safety: The automated process reduces the need for manual labor, saving time and reducing the risk of injuries associated with traditional cutting methods.

Maintenance-Friendly: Ultrasonic cutters do not require sharpening or frequent replacement, leading to reduced maintenance costs and downtime.

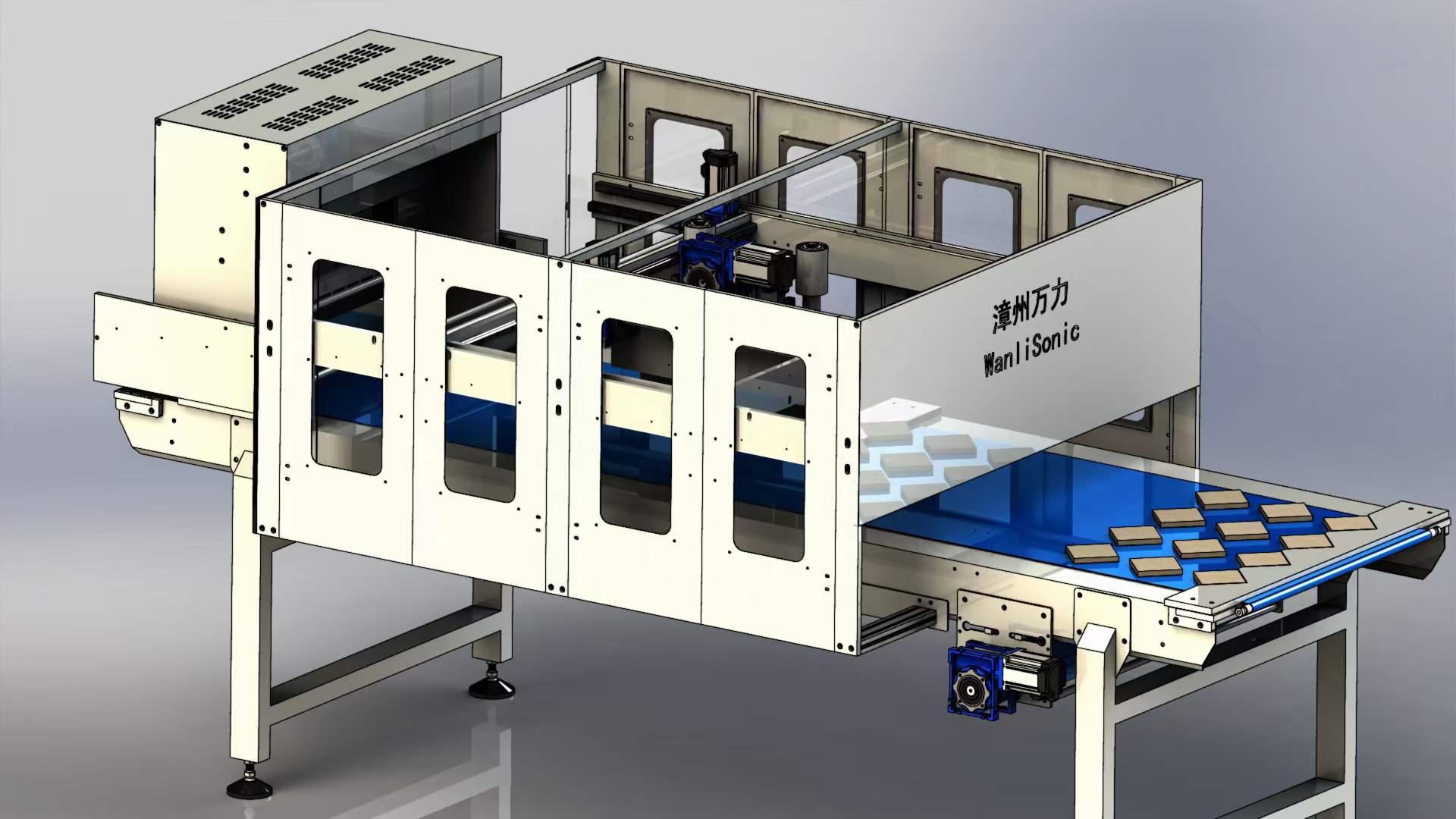

The Bread Cutting and Injecting Machine

The Bread Cutting and Injecting Machine combines the precision of ultrasonic cutting with the versatility of cream filling capabilities, making it an all-in-one solution for bakeries. This machine is designed to streamline the production process, ensuring consistent results and maximum efficiency.

Cutting Mechanism

The ultrasonic cutting mechanism of this machine works by transmitting high-frequency vibrations through a specially designed tool, which is brought into contact with the bread. These vibrations create a rapid back-and-forth motion that effortlessly slices through the bread, leaving behind a clean and smooth surface. The adjustable settings allow for precise control over the thickness and consistency of the slices, catering to the specific requirements of different bread types and recipes.

Cream Injecting Capabilities

Once the bread has been cut, the machine seamlessly transitions into its cream filling function. This feature utilizes advanced injection technology to dispense a variety of fillings, including cream, jam, custard, or cheese, into the bread slices or rolls. The precise injection system ensures even distribution of the filling, enhancing the taste and appearance of the final product.

Automation and Customization

The Bread Cutting and Injecting Machine is highly automated, reducing the need for manual intervention and minimizing human error. The machine can be programmed to perform specific tasks, such as cutting a predetermined number of slices or filling each slice with a precise amount of cream. Furthermore, the machine offers customization options, allowing bakers to adjust settings based on their unique recipes and production needs.

Benefits for the Baking Industry

The integration of ultrasonic cutting and cream injecting capabilities into a single machine offers numerous benefits to the baking industry:

Increased Productivity: The automated process significantly reduces the time required for bread cutting and filling, allowing bakeries to produce more in less time.

Improved Product Quality: The precision of ultrasonic cutting and the even distribution of cream filling result in bread products with superior quality and consistency.

Cost Savings: By reducing waste, minimizing maintenance requirements, and streamlining production processes, the machine contributes to overall cost savings for bakeries.

Enhanced Safety: The automation of dangerous tasks such as cutting and filling reduces the risk of workplace injuries.

Flexibility and Versatility: The customizable nature of the machine allows bakeries to adapt to changing market demands and customer preferences.

Conclusion

In conclusion, the Bread Cutting and Injecting Machine equipped with ultrasonic technology represents a game-changing advancement in the baking industry. By harnessing the power of high-frequency vibrations, this machine enables precise and efficient bread cutting, combined with seamless cream filling functions. This dual functionality revolutionizes the way bread is produced, enhancing productivity, precision, and overall product quality. As the baking industry continues to evolve, the integration of innovative technologies such as ultrasonic cutting will play a crucial role in shaping its future.