Revolutionizing Baking: Ultrasonic Brownie Cutting Machine

Baking enthusiasts, rejoice! The culinary landscape is undergoing a transformation with the advent of the Ultrasonic Brownie Cutting Machine. In this article, we’ll take you on a journey through the evolution of baking technology, the challenges in traditional brownie cutting, and the groundbreaking innovation that is set to redefine precision in the factory.

Introduction

In the dynamic landscape of culinary arts, the evolution of baking technology has been nothing short of a revolution. From the early days of manual tools to the current era where technology seamlessly integrates with our culinary pursuits, the journey has been remarkable.

The Progress of Baking Tools

Baking started as a manual craft, with bakers relying on basic tools like wooden spoons, hand-turned mixers, and traditional ovens. The simplicity of these tools reflected the essence of the craft but also posed limitations on efficiency and precision.Fast forward to the present, and we find ourselves in an era where baking has embraced cutting-edge technology. Advanced baking tools, powered by sophisticated machinery, have transformed the way we approach the art of baking. The integration of technology has not only streamlined processes but has also given rise to new possibilities, particularly in industrial settings.

Challenges in Traditional Brownie Cutting

Despite the leaps in technology, certain aspects of baking, like brownie cutting, have presented persistent challenges. Traditional brownie cutting methods, rooted in manual processes, often resulted in inefficiencies. The reliance on handheld tools led to unevenly sized brownies, affecting the overall quality and presentation of the final product.Moreover, the manual approach to brownie cutting proved to be time-consuming. In a fast-paced culinary world, where efficiency is key, bakers found themselves grappling with the need for a more effective solution.

The Dawn of Innovative Solutions

Recognizing the challenges posed by traditional brownie cutting methods, the baking industry has witnessed a surge in innovative solutions.

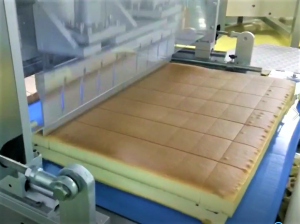

One such solution comes in the form of automated brownie cutting machines. These cutting-edge devices leverage technology to ensure precision and consistency in every cut. Equipped with advanced sensors and cutting mechanisms, these machines deliver perfectly sized brownies, meeting the high standards set by modern baking enthusiasts.

Integration of Artificial Intelligence

To take it a step further, some cutting-edge brownie cutting machines are now integrating artificial intelligence (AI). This entails machine learning algorithms that adapt and optimize the cutting process based on various factors, including brownie batter consistency and thickness.Benefits of Technological Advancements in Baking.The infusion of technology into the baking process brings forth a multitude of benefits.

Enhanced Efficiency

Automated brownie cutting machines significantly reduce the time and effort required for this task, enhancing overall kitchen efficiency. Bakers can focus on more intricate aspects of their craft, knowing that the cutting process is in capable hands.Precision and consistency are paramount in baking, and technology ensures that every brownie is cut to perfection. This not only elevates the visual appeal of the end product but also contributes to a consistently high quality that keeps customers coming back for more.The evolution of baking technology has opened doors to new possibilities, especially in large-scale production settings. With automated processes, bakeries can meet the demands of a growing market without compromising on quality.

The Technological Marvel

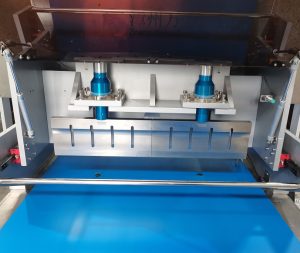

Enter the Ultrasonic Brownie Cutting Machine, a technological marvel that stands at the forefront of baking innovation. This cutting-edge device harnesses the power of ultrasonic waves, offering a level of precision and efficiency previously unattainable.

Precision and Efficiency Advantages

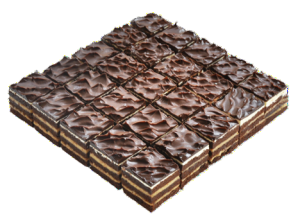

The Ultrasonic machine ensures perfect, uniformly sized brownies with each cut. Its ability to guarantee accurate sizing revolutionizes the baking process. Whether you are a home baker aiming for perfection or a commercial factory striving for efficiency, this machine is a game-changer. The time-saving benefits it provides make it indispensable in today’s fast-paced baking landscape.

How Ultrasonic Technology Works

Understanding the mechanism behind the Ultrasonic Brownie Cutting Machine is crucial to appreciating its revolutionary impact. This device employs ultrasonic waves, which are high-frequency sound waves beyond the range of human hearing. The waves create vibrations that effectively slice through brownies with unparalleled precision.

Benefits for Home Bakers

Elevating Home Baking Experiences

For home bakers, the Ultrasonic Brownie Cutting Machine offers a transformative experience. Achieving bakery-quality brownies at home becomes not just a possibility but a reality. The precision ensures that each brownie is a masterpiece, delighting family and friends alike.

Time-Saving Convenience

Beyond precision, the time-saving aspect of this machine is a boon for busy individuals. No more hours spent meticulously cutting brownies – the Ultrasonic machine handles the task efficiently, allowing more time for creativity and enjoyment in the factory.

Revolutionizing Commercial Baking

Consistency at Scale

In commercial baking, where large quantities are the norm, the Ultrasonic Brownie Cutting Machine ensures consistency at scale. The days of inconsistent sizes and labor-intensive processes are replaced with a streamlined approach that meets the demands of the modern market.

Operational Efficiency

Operational efficiency is paramount in a commercial setting. The Ultrasonic machine not only guarantees precision but also enhances the overall efficiency of the baking process. This translates to reduced production time and increased output, ultimately impacting the bottom line positively.

User-Friendly Design

One of the standout features of the Ultrasonic Brownie Cutting Machine is its user-friendly design. It caters to all skill levels, ensuring that even those new to baking can effortlessly create perfect brownies. The intuitive controls and straightforward operation make it a must-have for anyone passionate about baking.While boasting cutting-edge technology, the machine maintains a perfect balance by incorporating user-friendly elements. Its interface is designed with simplicity in mind, proving that sophistication can coexist with ease of use.

Impact on Baking Industry

This innovation is not just a gadget; it’s a game-changer for the baking industry. By revolutionizing baking processes, the Ultrasonic machine is generating increased demand for precision equipment. It’s reshaping how brownies are prepared and presented, setting new standards in the culinary world.As word spreads about the Ultrasonic Brownie Cutting Machine’s impact on baking, there’s a noticeable surge in demand for precision equipment. Bakers worldwide are recognizing the need to elevate their craft with tools that not only enhance efficiency but also guarantee a level of precision that was previously hard to attain.The ripple effect of this innovation is evident in how brownies are now prepared and presented across the globe. The Ultrasonic machine is not just a tool; it’s a catalyst for change, reshaping culinary narratives and inspiring a new era of precision and perfection in baking.

Comparisons with Traditional Methods

Let’s pit tradition against innovation. The Ultrasonic machine outshines traditional methods, not only in the precision of results but also in the time it takes to achieve perfection. Discover why this machine is rapidly gaining favor among bakers of all levels.

1. Precision in Every Cut

Traditional methods often involve a degree of uncertainty in achieving precise cuts. The Ultrasonic machine, however, has changed the game. Its cutting-edge technology ensures every brownie is cut with unparalleled precision, eliminating the guesswork that comes with traditional methods.

2. Time Efficiency

In the fast-paced world of baking, time is of the essence. The Ultrasonic Brownie Cutting Machine not only delivers precise results but does so in a fraction of the time compared to traditional methods. This time efficiency is a game-changer for both home bakers and professionals, allowing them to focus on creativity rather than the intricacies of cutting.

3. Consistency Across Batches

Bakers often grapple with maintaining consistency across batches when using traditional methods. The Ultrasonic machine addresses this challenge head-on. Whether you’re making a small batch or catering to a large event, the machine ensures uniformity, setting a new standard for the industry.

Maintenance and Longevity

Concerned about the upkeep of such advanced equipment? Fear not. Our article provides practical tips for maintaining the Ultrasonic Brownie Cutting Machine, ensuring it stays in optimal condition for the long run. The initial investment is a small price to pay for the long-term benefits it brings.Proper maintenance is key to ensuring the longevity of your Ultrasonic Brownie Cutting Machine. Here are some practical tips to keep your equipment in optimal condition:

1. Regular Cleaning

Frequent cleaning is essential to prevent any buildup of batter or debris. Follow the manufacturer’s guidelines for cleaning and use mild, non-abrasive cleaning agents to avoid damaging sensitive components.

2. Lubrication of Moving Parts

Ensure that all moving parts are adequately lubricated to prevent friction and wear. Regularly check and lubricate hinges, blades, and other components to maintain smooth operation.

3. Calibration Checks

Periodically check and calibrate the machine to ensure precision in cutting. Calibration ensures that the Ultrasonic technology functions at its best, providing consistent and accurate results.

4. Professional Servicing

Consider professional servicing at regular intervals. Expert technicians can identify and address any potential issues before they escalate, extending the life of your machine.

Cost Considerations

While the Ultrasonic Brownie Cutting Machine represents an initial investment, the long-term benefits far outweigh the upfront cost. Let’s explore the cost considerations that make this machine an economical choice for various user groups.

Time Savings

Time is money, especially in the fast-paced world of baking. The Ultrasonic machine significantly reduces the time required for precise brownie cutting, allowing bakers to increase production without compromising quality.

Resource Efficiency

The machine’s efficiency goes beyond time savings; it optimizes the use of ingredients, reducing waste. Precise cutting ensures uniform portions, minimizing excess trimmings and maximizing the use of raw materials.

Versatility

The versatility of the Ultrasonic machine adds to its cost-effectiveness. Its ability to handle various types of batters and recipes makes it a valuable asset for both small bakeries and large-scale production facilities.

Customer Satisfaction

Happy customers are repeat customers. The consistent quality achieved with the Ultrasonic Brownie Cutting Machine contributes to customer satisfaction, leading to increased sales and business growth.

Availability and Suppliers

Ready to bring this baking marvel into your factory? The article guides you on where to purchase the Ultrasonic Brownie Cutting Machine and identifies reliable suppliers in the market. Ensure you get an authentic product to enjoy the full benefits of this revolutionary technology.

Future Developments

The excitement doesn’t stop here. Explore potential advancements in baking technology as we discuss the future developments that could further transform your factory. Stay tuned for what innovation might have in store for your baking endeavors.

Conclusion

In conclusion, the Ultrasonic Brownie Cutting Machine isn’t just a factory appliance; it’s a revolutionary force. Its precision, efficiency, and user-friendly design set new standards for brownie preparation. Embrace this technological shift and elevate your baking game to new heights.