Understanding Ultrasonic Cutting Machine

Why choose ultrasonic blades to cut food?

The ultrasonic blade is the most important part of the ultrasonic food-cutting machine. Ultrasonic cake cutting machine is a device that uses ultrasonic energy to cut. Compared to traditional cutters, ultrasonic food cutters are more hygienic, have less downtime, are more cost effective, have more consistent cutting surfaces, and have blades that stay sharp longer.

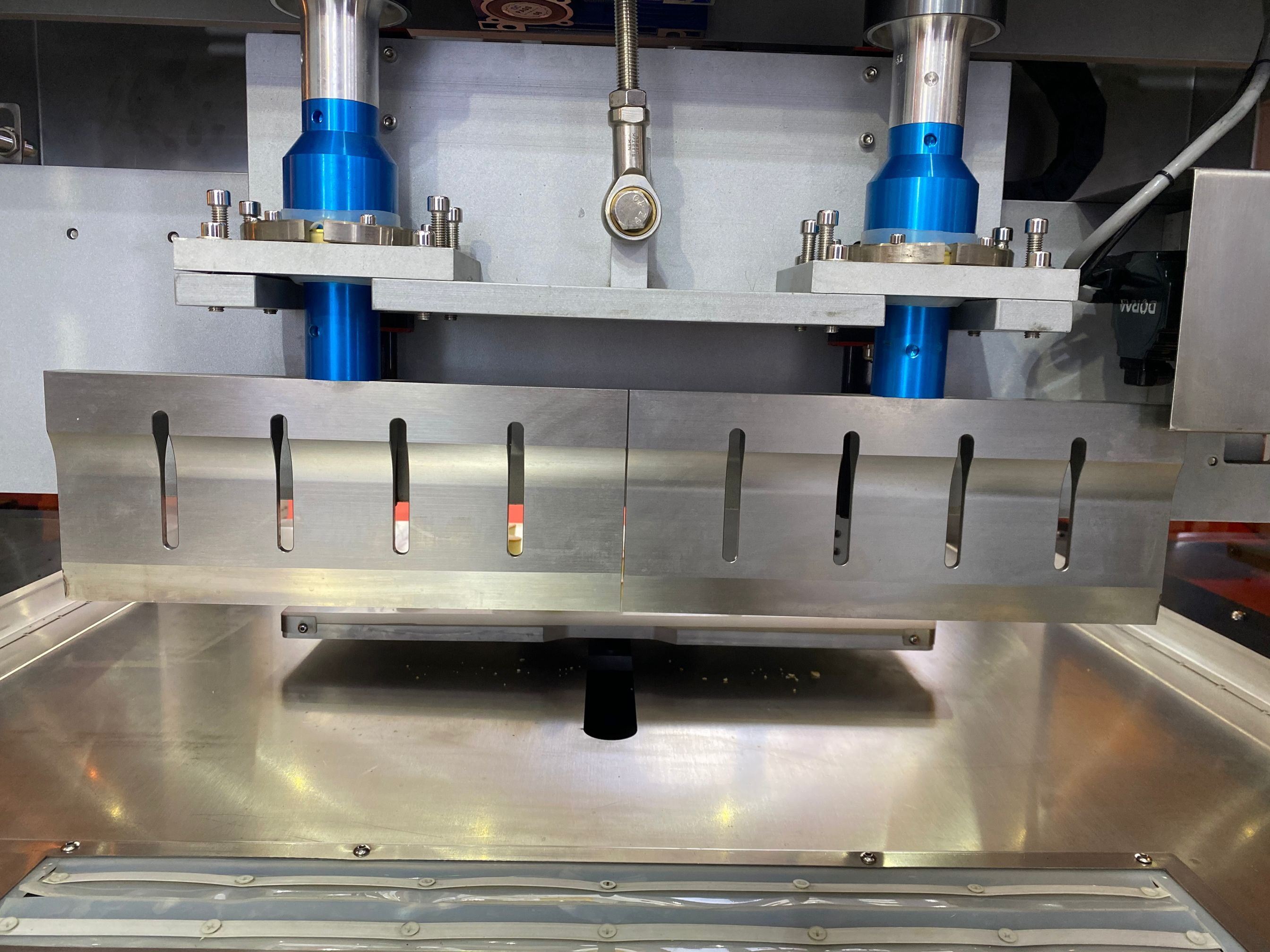

After years of development, the development of ultrasonic technology makes it possible to use ultrasonic product cutting, ultrasonic cutting technology continues to develop and improve, ultrasonic food cutting machine is currently in the major food industry have a wide range of applications, and has achieved good results. Wanli’s ultrasonic cutting machine can vibrate its blade 50,000-60,000 times per second (50-60 kHz). This high-frequency vibration, ultrasonic cutting machine can easily cut food. The application of ultrasonic cutting food is currently widely used in bread, cake, dessert, cheese, candy, meat and other food cutting. The length and height of the ultrasonic blade may vary and can be customized depending on the specific requirements of the customer and the existing conditions of the ultrasonic cutting machine.

Our ultrasonic cutting knives are made of titanium, a completely inert material recognized by the food industry. Titanium has good fatigue strength, surface hardness and excellent acoustic properties.

Cutter principle

Ultrasonic cake cutting tool is the use of ultrasonic energy to cut the local vibration of the material to be cut, so as to achieve the purpose of material cutting, traditional cutting is the use of a tool with a sharp edge, press to the material to be cut, the pressure is concentrated at the cutting edge, the pressure is very large, more than the shear strength of the material to be cut, the molecular bond of the material is pulled apart, it is cut off. Ultrasonic cake cutting has a great advantage, that is, at the same time of cutting, there is fusion in the cutting part, the cutting part is perfectly sealed, which can prevent the loose organization of the cut material, so the ultrasonic cutting does not need a sharp edge, does not need a lot of pressure, will not cause the edge of the cut material, damage, cutting knife when making ultrasonic vibration, The friction resistance is very small. The high-frequency signal generated by the ultrasonic vibration system is transmitted to the ultrasonic transducer, converted into sound waves, and transmitted to the ultrasonic cake cutting edge through the amplitude transformer, converting the sound wave energy into mechanical vibration energy to achieve the function of cutting vibration, and using the cutting edge of the cutting tool, the ultrasonic energy is concentrated into the cutting part of the material to be cut. Under the action of huge ultrasonic energy, the part instantly softens, melts, and the strength decreases. At this time, the purpose of material cutting can be achieved as long as a small cutting pressure is applied.

The principle of the ultrasonic cake cutting machine is completely different from the traditional sense of cutting. It uses the energy of ultrasound to melt the local heating of the material to be cut, so as to achieve the purpose of cutting the material. Therefore, ultrasonic cutting does not need a sharp edge, nor does it need a lot of pressure, and will not cause the edge collapse and damage of the material to be cut. At the same time, because the cutting knife is doing ultrasonic vibration, the friction resistance is particularly small, and the cut material is not easy to stick to the blade. This is especially effective for cutting viscous and elastic materials, frozen materials such as food, rubber, etc., or objects that are not easy to apply pressure.

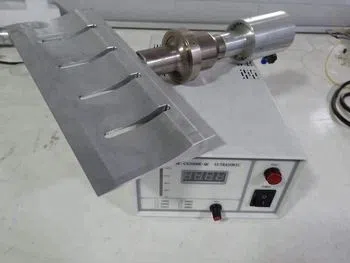

The basic composition of ultrasonic cutting machine is ultrasonic transducer, amplitude transformer, cutting knife (tool head), driving power. The ultrasonic drive power converts the mains power into high-frequency high-voltage AC current, which is fed to the ultrasonic transducer. The ultrasonic transducer is actually equivalent to an energy conversion device, which can convert the input electrical energy into mechanical energy, that is, ultrasound. Its manifestation is that the transducer moves back and forth longitudinally. The frequency of the telescopic motion is equivalent to the frequency of the high-frequency AC current supplied by the driving power supply. The function of the amplitude converter is to fix the whole ultrasonic vibration system, and to amplify the output amplitude of the transducer. The cutting knife (tool head) on the one hand further amplifies the amplitude and focuses the ultrasonic wave. On the other hand, the output ultrasonic wave uses the similar edge of the cutting knife to concentrate the ultrasonic energy into the cutting part of the material to be cut. Under the action of huge ultrasonic energy, the part is softened and melted instantaneously, and the strength is greatly reduced. At this time, as long as a small cutting force is applied, the purpose of cutting the material can be achieved.

Similar to conventional cutting, the basic components required are cutting knives and cutting boards, and ultrasonic cutting machines also have two basic structures. According to the different position of ultrasonic application, we may wish to divide it into ultrasonic cutting knife cutting machine and ultrasonic cutting board cutting machine.

The ultrasonic cake cutting machine directly loads the ultrasonic energy onto the cutting knife, and the cutting knife becomes a cutting knife with ultrasonic waves. When cutting the material, the material is mainly softened and melted by ultrasonic energy, and the cutting edge of the cutter only plays the role of slit positioning, ultrasonic energy output, and separating the material. This cutting method is suitable for the cutting of thick, thick, long and other materials that are not convenient to set the cutting board. Such as rubber mixer output of raw rubber cutting, pipe cutting, frozen meat, candy, chocolate cutting, printed circuit boards, or hand-held cutting machines and so on.

The basic structure of the ultrasonic cutting machine is similar to that of the ultrasonic cutting machine, except that the ultrasonic output part is not a cutting knife, but a standard ultrasonic plane mold. In this case, the mold acts as a cutting board. Except, this is a cutting board being vibrated by ultrasound. The cutting knife is still the traditional, any shape can be used, but the sharpness of the cutting edge requirements have decreased, and the life of the cutting knife has been greatly extended.

The basic composition of acoustic cutting machine

- Ultrasonic transducer

- Ultrasonic amplitude converter

- Ultrasonic cutting knife

- Ultrasonic generator

(1) Folding ultrasonic generator

The mains electricity is converted into high-frequency high-voltage AC current, which is fed to the ultrasonic transducer. Ultrasonic transducers are equivalent to energy conversion devices, which can convert the input electrical energy into mechanical energy, that is, ultrasonic waves. The ultrasonic transducer moves back and forth lengthwise, and the frequency of the movement is equal to the frequency of the high-frequency AC current supplied by the driving power supply.

(2) Folding ultrasonic horn

Ultrasonic amplifiers amplify the output amplitude of ultrasonic transducers.

(3) Folding ultrasonic cutting knife

Further amplifying the amplitude, focusing the ultrasound.

The ultrasonic wave is output, and the ultrasonic energy is concentrated into the cutting part of the material to be cut by using the cutting knife. Under the action of huge ultrasonic energy, the part softens and melts instantly, and the strength decreases obviously. Only a small amount of force is needed to achieve the purpose of cutting the material.

Application prospect

Ultrasonic food slicer is a device that uses ultrasonic waves generated by high-frequency oscillations to cut food. Compared with the traditional mechanical cutting method, ultrasonic cutting has the advantages of smooth cutting surface, high cutting precision, high cutting efficiency and no noise in the cutting process. It is suitable for cutting all kinds of soft and hard food, such as bread, meat, cheese, vegetables and so on. In addition, ultrasonic cutting can also reduce bacterial contamination in the food cutting process to ensure food hygiene and safety. Therefore, ultrasonic food slicer has broad application prospects in food processing, catering industry and other fields.

Ultrasonic Cutting Basic Structure

Ultrasonic cake cutting machine is a type of equipment that uses wave energy for cutting. Its biggest feature is that it does not need a cutting edge. In other words, no traditional cutting edge is needed. Traditional cutting is to use a knife with a sharp edge to press against the material being cut. This pressure is concentrated at the edge of the blade, and the pressure is very large, exceeding the shear strength of the material being cut, and the molecular bond of the material is pulled apart and cut off. Because the material is pulled apart by strong pressure, the cutting edge of the cutting tool should be very sharp, and the material itself must withstand relatively large pressure. It is not good for cutting soft and elastic materials, and it is more difficult for sticky materials.

The basic structure is an ultrasonic transducer, horn, cutter (tool head), and drive power. The ultrasonic drive power converts the city power into high-frequency high-voltage alternating current, which is transmitted to the ultrasonic transducer. Ultrasonic transducer is actually equivalent to an energy conversion device, it can convert the input electrical energy into mechanical energy, that is, ultrasound. Its manifestation is that the transducer moves back and forth in the longitudinal direction. The frequency of the telescopic movement is equal to the frequency of the high-frequency alternating current supplied by the driving power supply. The role of the horn is to fix the entire ultrasonic vibration system, and second to amplify the output amplitude of the transducer. On the one hand, the cutter (tool head) further amplifies the amplitude and focuses the ultrasound. On the other hand, it outputs ultrasonic waves, and uses a similar edge of the cutting blade to concentrate the ultrasonic energy into the cutting site of the material to be cut. Under the action of huge ultrasonic energy, this part instantly softens and melts, and its strength drops greatly. At this time, as long as a small cutting force is applied, the purpose of cutting the material can be achieved. Similar to conventional cutting, the basic components required are the cutter and the cutting board, and the ultrasonic cutting machine also has two basic structures.

Ultrasonic Generator

Ultrasonic power supply is divided into self-excited power supply and other excited power supply, self-excited power supply is called ultrasonic analog power supply, and its excited power supply is called ultrasonic generator. Ultrasonic generator, also known as ultrasonic drive power supply, electronic box, ultrasonic controller, is an important part of high-power ultrasonic system. The function of the ultrasonic generator is to convert the commercial power into a high-frequency alternating current signal matched with the ultrasonic transducer to drive the ultrasonic transducer to work.

The ultrasonic generator generates a sinusoidal signal or pulse signal of a specific frequency, and this specific frequency is the working frequency of the transducer. The ultrasonic frequency applied in the ultrasonic equipment is 20KHz, 25KHz, 28KHz, 33KHz, 40KHz, 60KHz and above 100KHz.

The ultrasonic generator has a feedback link, which mainly provides feedback signals in two aspects: the first is to provide an output power signal, and the second is to provide a frequency tracking signal.

Advantages of intelligent ultrasonic generator (compared to analog type):

- Automatic follow-up: Once the device is initially set up, it can work continuously without the need to adjust the generator.

- Automatic amplitude control: when the load changes during the operation of the transducer, it can automatically adjust the driving characteristics to ensure that the tool head gets a stable amplitude.

- System protection: When the system works in an unsuitable operating environment, the generator will stop working and display an alarm to protect the equipment from damage.

- Amplitude adjustment: The amplitude can be increased or decreased instantaneously during the work. The setting range of the amplitude: 0%~100%.

- Automatic frequency search: The working frequency of the tool head can be automatically determined and stored.

- Overheat protection: It can well protect the generator from being damaged.

High frequency ultrasound

Ultrasound refers to a mechanical wave (frequency>20 kHz) that exceeds the hearing range of the human ear, and the higher frequency type (frequency>100 kHz) is called high-frequency ultrasound. The frequency of current ultrasonic equipment is generally in the range of 20 kHz to 10 MHz. As an advanced food processing technology, ultrasound has the characteristics of mild action and strong pertinence. It is widely used in food and other fields and has great development prospects.

According to the frequency and power of ultrasonic waves, ultrasonic waves can be divided into two categories: high-power low-frequency ultrasonic waves and low-power high-frequency ultrasonic waves. Among them, high-power low-frequency ultrasound (frequency between 20 and 100 kHz) is also known as power ultrasound, which has a wide range of applications in food processing. Low-power high-frequency ultrasound (its frequency is mainly concentrated in 100 kHz to 10 MHz) is not only used in medical diagnosis, but also widely used in the analysis and monitoring of food physical and chemical properties, such as hardness, maturity, sugar, acidity, etc.

Advantages of ultrasonic cake cutting machine

- The cutting surface is neat, no debris

Ultrasonic cake cutting will locally heat the cutting surface of the food during the cutting process, and play a fusion role in the cutting part, so the cutting surface of the food can be perfectly sealed, and the internal structure of the food can be avoided while maintaining the beauty.The cutting surface is so neat during the cutting of the product that hardly any food residue falls off. The machine is capable of precise cutting and the blades are sharpened by ultrasonic cutting. The cutting surface is very neat and the cutting process will not destroy the original appearance of the product, to ensure the quality of the product, to give customers a good quality assurance. - Food will not stick to the blade.

When cutting some sticky food, the food will not stick to the blade and reduce the contact with the food. Keep the original flavor of the food. Sticky food cut with ordinary blades tend to stick to the knife, and the blade is very difficult to clean, the use of ultrasonic blade will not only not stick to the blade, but also to maintain the shape and integrity of the product. - No easy deformation during the cutting process of the product

When cutting some hard or soft products, the food is not easy to deform during the cutting process, for example, cutting nougat makes, the food is not easy to break, to maintain the integrity of the food. When cutting soft cake, the cake will not be easily deformed due to pressure. When cutting frozen cheese, it does not destroy the cheese’s appearance can be both cubed and sliced, and can keep the size and shape of each product uniform. - Hygienic, less bacteria

The cutting process is hygienic and low in bacteria. Vibratory cutting occurs when the blade touches the food, less contact with the food, avoiding contact with bacteria. If the food has bacteria on it, this can easily lead to a shorter shelf life of the product. Choose ultrasonic cutting, which reduces the propagation of bacteria and is clean and hygienic. This is a point that many consumers value.

- High efficiency, large capacity

Ultrasonic cake cutting technology is very different from the general cutting, which can be used to ensure the precision cutting, not to damage the cutting product, and the most extent of the cutting material is retained. The ultrasonic cake cutting knife is carried out by a driving system with precision and rapid servo drives, which can accelerate the progress of cutting and reduce the amount of energy that ultrasonic cake cutting machines can burn. The use of ultrasonic cake cutting machines to integrate into industrial processes can maximize time, increase productivity and increase productivity.Ultrasonic cake cutting machines are known for their high-speed cutting capabilities, which significantly increase productivity. The ultrasonic vibrations allow for faster and more precise cutting, reducing the time required for each cutting operation. - Environmental protection and no noise

Cutting environmentally friendly and no noise, with environmentally friendly recyclable materials, the cutting process is mainly through the vibration cutting, does not produce noise, reducing sound pollution, cutting a quiet environment, a good working environment.Ultrasonic blades produce only a small amount of noise during the cutting process and do not require the use of other equipment for anti-noise treatment, nor do they cause harm to the human body. Ultrasonic cutters do not negatively impact the ecosystem.The ultrasonic blade will only produce a small noise during the cutting process, and there is no need to use other equipment for anti-noise treatment, and it will not cause harm to the human body. Ultrasonic cutting machines do not negatively affect the ecosystem. - Stainless steel frame

The use of stainless steel frame, can increase the service life of the machine, the machine is not easy to rust affect the quality of the product. Long service life, in the process of use, not easy to machine error, and not easy to break down, long shelf life. - Easy to clean

The machine is very easy to clean and is simple to operate with just ordinary tools. The machine cleaning process does not need to use special tools for cleaning, only needs to use ordinary rags for cleaning can be, a simple wipe to keep the machine neat and clean. This will also extend the life of the machine. When it comes to cutting food, food hygiene is of Paramount importance. The process of operating ultrasonic food cutting requires strict hygiene conditions to reduce the risk of food contamination. At the same time, due to the low friction characteristics of the ultrasonic cutting knife, there is little adhesion when cutting food, keeping the blade clean while reducing the cleaning cost. - Precise cutting at any angle

Compared with traditional cutting tools, the cutting quality obtained by using ultrasonic cutting machines is much better. Ultrasonic cutting machines have extremely high accuracy and can better meet various cutting restrictions in industrial environments. The ultrasonic cutting knife is small, convenient, and flexible, and can be combined with automatic equipment to achieve the purpose of cutting food at any Angle and obtain the ideal food form to the greatest extent. - Not need a sharp blade

It does not need a sharp blade, does not need a lot of pressure, and will not collapse and damage the cutting material. Ultrasonic cutting will locally heat the cutting surface of the food during the cutting process, and play a fusion role in the cutting part, so the cutting surface of the food can be perfectly sealed, and the internal structure of the food can be avoided while maintaining the beauty.

Different traditional cutting

Ultrasonic cutting machine is the use of wave energy for cutting processing equipment, the biggest feature is not to use traditional cutting edge. Traditional cutting uses a knife with a sharp edge that is pressed into the material being cut. The pressure is concentrated at the cutting edge, the pressure is very large, exceeding the shear strength of the material to be cut, and the molecular bonds of the material are pulled apart and cut open. Since the material is pulled apart by strong pressure, the cutting tool edge should be very sharp, and the material itself should also withstand relatively large pressure. The cutting effect is not good for soft and elastic materials, and it is more difficult for viscous materials.

- High stability: The ultrasonic generator will generate high-frequency vibration when it is working, and it will be converted into mechanical vibration and transmitted to the cutting knife and the food, and it will be cut mechanically. Since the cutting is performed by high-frequency vibration, no sharp equipment is required, and the blade wear is also less.

- Non-polluting, safe, and hygienic: When using ultrasonic to cut food, the temperature of the equipment is lower than 50 degrees Celsius, and no smoke and odor will be generated, which eliminates possible damage during cutting.

- Neat cutting shape: Ultrasonic cuts through high-frequency vibration, food will not stick to the knife surface, only need to use less pressure when cutting, and will not easily deform and wear on fragile and soft materials.

- Easy to use: The blade of the ultrasonic food cutter can be replaced at any time, and the operation process is fast. During the cutting process, frequent cleaning of the knife is not required, and the low-friction cutting surface can slice a variety of foods cleanly without smearing, making it easy to cut.

- Not easy to mix color and odor: Since the cutting knife is not conducive to cutting edge cutting, it has less friction with food, and it is not easy to contaminate the smell and color of some food. When changing food for processing, food processing can be directly carried out to avoid shutdown, cleaning, and other parts of operation.

- Efficient cutting to avoid waste: The ultrasonic food cutting machine can cut the food shape accurately, improve the cutting quality of the food, and keep the particles such as nuts and fruits in a clean and non-displaced state, thus avoiding excessive material waste, which is very convenient. Save production costs to a large extent.

Products that can be cut

- Cake

Cake is an ancient pastry, usually made in the oven. The cake is made with eggs, sugar, and wheat flour as the main ingredients. Milk, fruit juice, milk powder, spices, salad oil, water, shortening, and baking powder as supplementary ingredients. After mixing, modifying, and baking to make a sponge-like confection.

- Bread

Bread is generally a food made from ground wheat and heated. Wheat flour as the main raw material, yeast, eggs, fat, sugar, salt, and other auxiliary materials, water modulation into a dough, after dividing, molding, rising, baking, cooling, and other processes processed into baked goods.

- Dough

Dough refers to the use of grain flour (flour, rice flour and miscellaneous grain flour, etc.) mixed with appropriate water, oil, eggs, molasses and other liquid raw materials and ingredients, after modulation to make the powder particles bonded to each other and formed for the production of semi-finished products or finished products of the homogeneous mixture of the dough, slurry of the general term.

- Cheese

Cheese, also known as cottage cheese, is a fermented milk product that has similar properties to the common sour milk, both are made through a fermentation process, and both contain lactic acid bacteria that can be used for health care, but cheese has a higher consistency than yogurt and approximates a solid food.

- Nougat

Nougat refers to candies made from roasted nuts and honey, and is available in two types: soft and hard. The soft ones are white nougat made with egg whites, while the hard ones are coffee-colored and made with caramel, with a hard and crunchy texture. Traditionally, nougat is mainly produced in Spain and consists mainly of roasted almonds, followed by honey and egg whites.

- Cookies

Cookies to wheat flour, sugar, dairy products as the main raw materials, adding fluffing agent and other

auxiliary materials, in order to and flour, using extrusion injection, extrusion strips, steel wire knuckle cutting and other methods of one of the forms of molding, baking made of three-dimensional pattern or the surface of the surface of the regular ripples, high fat content of the crispy baked goods.

- Butter

Butter is a kind of solid fat processed from milk, which is the product of filtering out some of the water from the top layer of a thick object after mixing fresh milk. Butter, also known as cream, white skimmed oil, is made by separating the thin cream and skimmed milk in milk, and then ripening the thin cream and stirring it.

Benefits of choosing ultrasonic cutting

- Larger capacity than ordinary cutting machines

As a machine user, we tend to pay more attention to the capacity of the machine, the larger the capacity for the machine user is about favorable. Large capacity means saving time, in the same time, can produce more products, which is the best for manufacturers is also their most important point!

- Long service life of the machine

If a machine has a long service life, the more value it can create for us. Purchasers often have to consider many aspects, this is something they have to consider. All parts of the machine are made of the best materials, and we have high quality requirements for the machine to ensure that it is safe for the buyer to use. Generally the machines do not go wrong during use.

- The machine is not easy to break down

The machine is very stable in operation and usually no error occurs. When an error occurs in the machine, it will automatically alarm us with a sound to remind us that we need to check it before operating it.

- Simple operation

The machine is mainly operated through a screen, just click on the program on the screen, the machine can be operated according to what you need. The operation is very simple and does not require you to learn any skills. The blade of the ultrasonic food cutter can be replaced at any time, and the operation process is fast. During the cutting process, frequent cleaning of the knife is not required, and the low-friction cutting surface can slice a variety of foods cleanly without smearing, making it easy to cut.

- Precise cutting

The machine will cut accurately according to the program you have chosen, and the error of cutting is controlled within 1mm, the error is negligible. This can better ensure the quality of the product, so that the cut out food size and shape uniformity.The quality of cut that can be achieved with an ultrasonic cutting machine is much better than that of conventional tool cutting. Ultrasonic cutters are extremely accurate and can better meet the various cutting constraints in industrial environments. Ultrasonic cutting knives are small, convenient and flexible, and can be combined with automated equipment to achieve the purpose of cutting food products at any angle to maximize the ideal food form.

- Fully automatic equipment, saving labor costs

The equipment is fully automatic, no need for manual operation. The machine can run all the time without manual intervention, reducing labor and saving labor costs. Improvement in production efficiency means that the effective utilization of resources can be improved, and improving production efficiency is the root of cost reduction. Only when efficiency is improved can the marginal cost of the plant be reduced, and the break-even point can be lowered.

The use of ultrasonic cutting machine

In the cutting process, we often encounter many problems, such as the accuracy of cutting, the stability of the physical properties of the final product, the smoothness of the cutting surface, the difficulty of separating the cutter from the material, and the separation of the cutter surface and the material during separation The amount of residual materials in hard devices. When the characteristics of the materials are not clear, it is difficult for us to meet the above requirements.

For example, for materials with high hardness, strong brittleness, and strong viscosity, the traditional cutting method is difficult to complete. As the uncertainty of product materials increases, the difficulty of cutting work becomes more and more difficult. Ultrasonic food cutting is an optimization of traditional cutting. Ultrasonic food slitting not only increases the cutting speed, but also makes great progress in improving the structure, shape and performance of food.

Although for most products, ultrasonic cutting can reduce the cutting force required for the cutting process, but for some products, the material is also considered. Usually the cutting factor is between 0.1-1.0. If you study the macro structure and mechanical properties of food in the cutting process, consider the types of materials for cutting food. Therefore, distinguish the following two types of materials.

- For uniform and dense materials, such as high-fat foods, cheese, etc. These foods are characterized by a non-porous and compact structure. In the traditional cutting process, a lot of friction is often generated, and the magnitude of the friction is related to the viscosity of the material. Ultrasonic cutting can reduce the interaction force between the cutter and the material during the cutting process, thereby avoiding plastic deformation. On the other hand, the energy consumption of this compact and non-porous structure during the cutting process also increases significantly.

- For porous foods, such as bread, cakes, marshmallows and other foods with similar structures, their common feature is a multi-hole sponge-like structure. Moreover, it is very easy to be compressed and deformed. If the traditional cutting tool is used, it can only reach part of the crack. If it is further cut, it will be twisted or broken. But if you use ultrasonic cutting, you will achieve good results. Because ultrasonic cutting can reduce the friction generated during the cutting process, the cutting work can be completed with a small cutting force. Finally, a neat and smooth cutting surface is achieved. Compared with the cutting of dense materials, the impact of friction on the cutting process during the cutting of porous materials is relatively small. Because the actual contact area between the cutter and the material during cutting is much smaller than the geometric area of the material. In addition, in the process of the tool entering the material, the porous material requires more energy than the dense material.

Ultrasonic toast slicing equipment

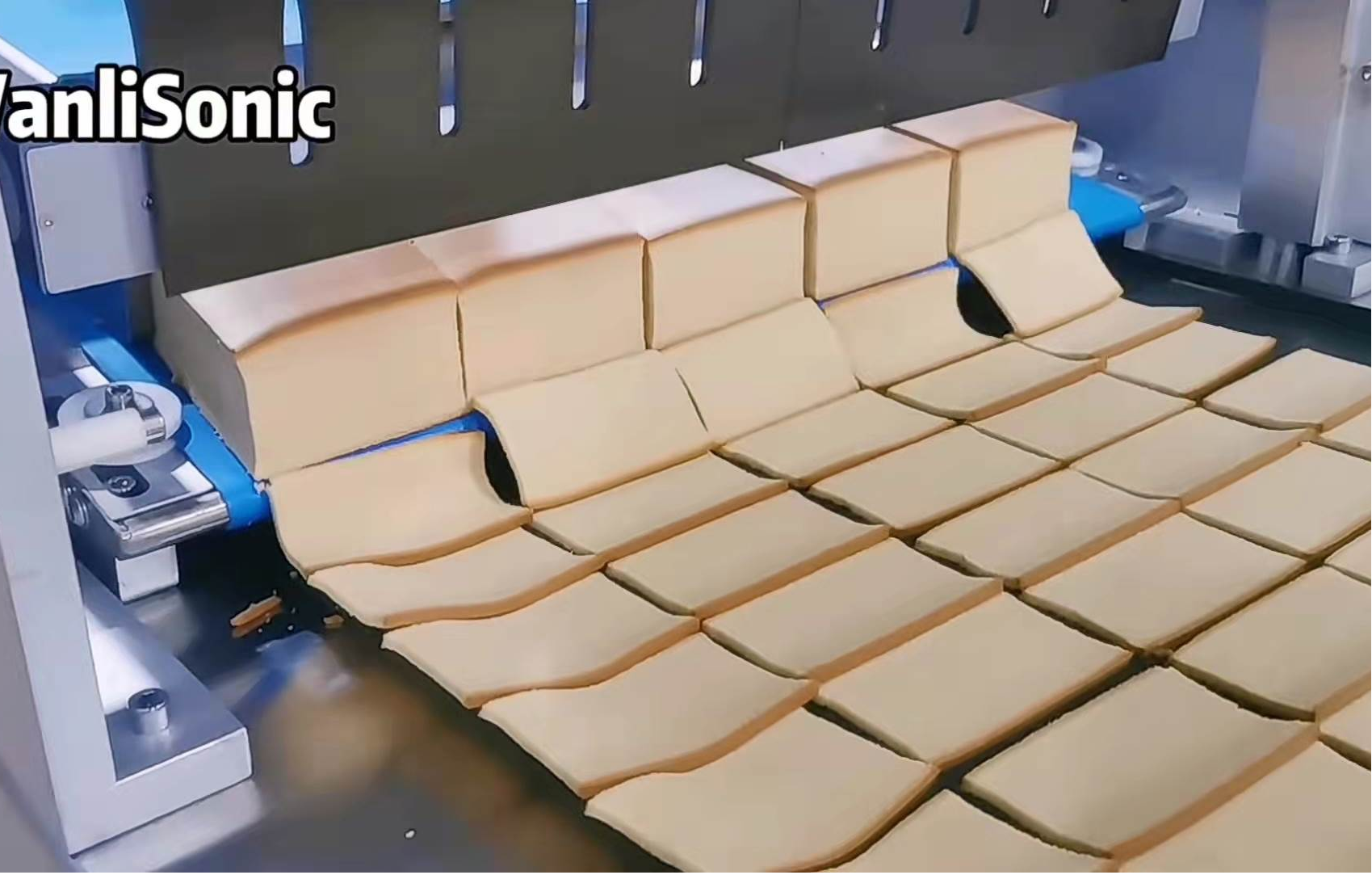

The bread slicing equipment production line is an efficient and highly automated bread slicing equipment. The equipment mainly through automatic feeding, slicing, arranging, stacking and other processes, to achieve a variety of bread and toast fast cutting and processing. At the same time, the equipment also has the function of material management, which can greatly improve the production efficiency and product quality. The equipment is made of high quality stainless steel, has the characteristics of compact structure, easy operation, easy maintenance, etc., suitable for central baking factory, food processing plant, etc.

Origin of ultrasonic toast slicing equipment

Toast is a type of bread and is arguably the most popular bread in the world. Whether in China, Europe or the United States, toast seems to be an ordinary food that is “everyday”. But in the world of baking, toast holds an unassailable place. Toast This kind of sliced bread is a loaf of bread that is made and cut into pieces of bread of equal thickness with a knife. Sliced bread, this is what we usually call toast. And to cut toast, you need to use a machine to cut. The use of machine cutting can not only improve the inefficiency brought about by manual cutting, reduce the production of labor, but also meet the increase in population demand and increase production. Therefore, the Wanli factory has developed an ultrasonic toast slicing device that can be used for mass production.

Briefly describe the ultrasonic toast slicing equipment

The bread slicing equipment production line is an efficient and highly automated bread slicing equipment. The equipment mainly through automatic feeding, slicing, arranging, stacking and other processes, to achieve a variety of bread and toast fast cutting and processing. At the same time, the equipment also has the function of material management, which can greatly improve the production efficiency and product quality. The equipment is made of high quality stainless steel, has the characteristics of compact structure, easy operation, easy maintenance, etc., suitable for central baking factory, food processing plant, etc.

Characteristics of ultrasonic toast slicing equipment

Ultrasonic toast slicing device, which is a custom machine designed for a continuous supply of product, slicing toast bread products into thin slices. This machine can automatically cut 1-10 pieces of toast side by side according to the width of the product. The tool holder can be equipped with 4-10 ultrasonic knife systems to cut fresh and sticky products. The machine has high cutting efficiency, can cut products with widths greater than 1 meter, and can produce 1,200 toast per hour.

The ultrasonic toast slicing device is an automatic cutting device for food factories that uses ultrasonic waves transmitted through titanium blades to cut the material into the desired shape and size. This kind of equipment usually has high-precision sensors and control systems, which can automatically adjust the cutting speed and position to ensure the accuracy and stability of the cutting.

The ultrasonic automatic slicing equipment of toast bread uses high frequency ultrasonic wave to realize the automatic slicing of bread, and the slice size and number can be adjusted arbitrarily. At the same time, the equipment also has a variety of safety protection measures to ensure the safety of the use process.

Apply

Ultrasonic toast slicing equipment is suitable for baking industry, with the advantages of fast cutting speed, high efficiency and low power consumption. Because the equipment adopts ultrasonic cutting technology, it can achieve sterile and pollution-free cutting to ensure the quality and safety of the product. It is very suitable for the automatic cutting line of baking pan cake bread in the baking industry.

It can be used to cut different types of toast, Swiss rolls, cheese, biscuits and other baked goods. Can be divided into different temperature states of food, such as baked goods and frozen food. And according to customer needs and existing conditions to propose customized ultrasonic solutions, welcome to sample testing.

Wanli’s ultrasonic food slicing equipment is a device that uses ultrasonic waves generated by high-frequency oscillations to cut food. Compared with the traditional mechanical cutting method, ultrasonic cutting has the advantages of smooth cutting surface, high cutting precision, high cutting efficiency and no noise in the cutting process. It is suitable for cutting all kinds of soft and hard food, such as bread, meat, cheese, vegetables and so on. In addition, ultrasonic cutting can also reduce bacterial contamination in the food cutting process to ensure food hygiene and safety. Therefore, ultrasonic food slicer has broad application prospects in food processing, catering industry and other fields.

Ultrasonic cutting application Ultrasonic can cut a variety of foods such as cakes, pies, cheese, pizza, bread, candy, etc. The cutting surface is clean and flat. When using ultrasonic equipment to cut foods like nuts or raisins, it can produce finer breaks than traditional cutting processes. Therefore, ultrasonic cutting food has more advantages than traditional methods: the cutting surface is clean and flat, the cutting knife has a longer service life, and more importantly, it can reduce the time of production shutdown due to cleaning and maintenance.

When cutting food, the ultrasonic cutter vibrates at a frequency of 20, kHz (or 30 / 40kHz) so that food debris will not remain on the surface of the knife. The surface of the food after cutting is very clean, and the separation between the layers is kept clear. The latest research shows that higher frequency (30 and 40 kHz) ultrasonic cutters are best for cutting hot and sticky foods, and there is no noise during the entire process.

Ultrasonic cutting system due to routine cleaning and maintenance caused by the shutdown time can be reduced by 70% ~ 90% compared to traditional equipment. If customers who use traditional cutting equipment want to use ultrasonic technology to process food, they only need to make small changes in the existing equipment; or introduce a new system design based on the existing production design. In this regard, we have very rich experience.

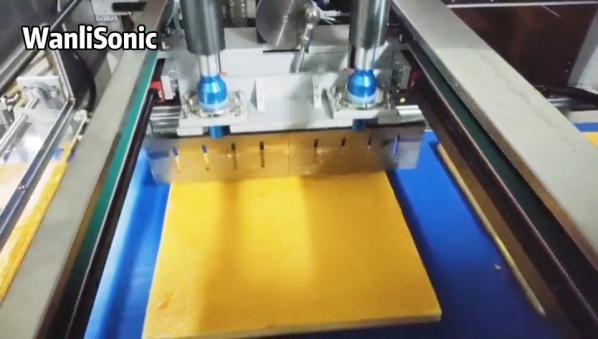

Rotary cake ultrasonic cutting machine is an ultrasonic food cutting machine designed for round and sheet cakes, frozen cakes or laminated bread cakes. The cutting height can be 60mm, 80mm or more. Ultrasonic cutting devices will vary according to your needs. Rotary Cake Ultrasonic Cutting Machine is our small ultrasonic cake cutting machine that uses the most innovative servo technology with industry-leading speed and precision.

The appearance of rotating cake ultrasonic cutting machine

Cake is an ancient west point, generally by artificial production, cake is made of eggs, sugar, wheat flour as the main raw materials. With milk, juice, milk powder, fragrance powder, salad oil, water, shortening, baking powder as auxiliary materials. It is stirred, mixed and baked into a sponge like pastry. After making various kinds of cakes by hand, they are cut and ready to be sold. And cutting different styles of cake, if you use manual cutting, there will always be a time when the cutting is not perfect, so a rotating cake ultrasonic cutting machine was born, its appearance perfectly solves the problems encountered in manual cutting, so it is loved by people.

The ultrasonic cake cutter is a special device specifically designed to cut cake, a popular dessert made from other ingredients such as cream, sugar and flour. These machines use high-frequency ultrasonic vibrations to precisely and clean fully cut cakes into uniform shapes and sizes, making them an essential tool for producing and selling cakes.

The working principle of the cake ultrasonic cutting machine is to use ultrasonic vibration to achieve accurate and clean cutting. When the machine is turned on, the ultrasonic generator generates high-frequency vibration and is transmitted through the metal blade or tool. These vibrations create a microscopic sawing effect that allows the blade to cut through the cake without crushing or deforming.

One of the main advantages of using ultrasonic vibration to cut a cake is that the process generates minimal heat and friction. This means that the cake is not damaged or melted during the cutting process and the final product retains its shape and quality.

Advantages of rotary cake ultrasonic cutting machine

1. Precise and efficient cutting is the biggest advantage of rotary cake ultrasonic cutting machine. The rotary cake ultrasonic cutting machine uses ultrasonic cutting technology, which is very different from the general cutting knife to cut the cake. The general cutting knife will cause the cutting surface of the cake to be uneven after cutting, and the cream is also easy to stick to the knife, which will destroy the surface of the cake, making it difficult to sell. The rotating cake ultrasonic cutting machine can ensure accurate cutting on the basis of not causing damage to the cut product, and retain the integrity of the cut material to the greatest extent. At the same time, the ultrasonic cutting system can speed up the progress of cutting, while making the ultrasonic cutting machine consume less energy, save time to the greatest extent, improve productivity and improve productivity.

2. Precise cutting at any Angle of different shapes: The use of rotary cake ultrasonic cutting machine to obtain better cutting quality. Ultrasonic cutting machines have extremely high accuracy and can better meet various cutting restrictions in various baking rooms. Rotary cake ultrasonic cutting machine to achieve the purpose of cutting food at any Angle, usually can cut rectangular, circular, and Swiss roll like long strip shape cutting, can also be customized triangular shape cutting, a variety of cutting needs, rotary cake ultrasonic cutting machine can do and maximize the ideal cake shape.

Clean and hygienic: For cakes, food hygiene is also a crucial requirement if they want to be sold to the public. The process of operating the rotary cake ultrasonic cutting machine is subject to strict sanitary conditions to reduce the risk of food contamination. At the same time, due to the low friction characteristics of the ultrasonic cutting knife, there is little adhesion when cutting food, keeping the blade clean while reducing the cleaning cost.

The rotary cake ultrasonic cutting machine is widely used in the baked goods industry. It is an ultrasonic food cutting machine designed for round and sheet cakes, frozen cakes or laminated bread cakes. It is also one of the best-selling models in our Wanli factory. The emergence of rotating cake ultrasonic cutting machine perfectly solves the problems encountered in manual cutting, and in cutting, whether from the appearance, quality or efficiency are far better than the general cutting knife, so it is loved by people and widely used in the food baking industry.

Machine component materials

- Ultrasonic blade

All of our ultrasonic blade is from Germany, It is made of TC11D and titanium Alloy. If operated correctly, it would be no problem even within 5 years. Made of Titanium Alloy material, The mechanical strength is better than that of steel, the acoustic transmission is good, the sound frequency is not depleted in its internal transmission, and it has strong acid-base corrosion ability.

- Energy transducer

Electric energy is converted to kinetic energy, to make the blade cut the products.

- Touch screen

Intelligence control, for the operation and monitor

- PCL control system

Anti-error operation, safety testing, alarm indication

- Relay

Touch switch

-

Conveyor Belt

Safe Food grade material

- Inverter

Driving the conveyor to work

- Servo motor

Driving the blade to work - Stepmotor

Driving the blade to work - Ultrasonic generator

The advantages of original ultrasonic generator include automatic frequency lock function, automatic frequency tracking, automatic amplitude limit(decrease the amplitude when the load is light), automatic temperature adaptation, wide frequency range of self-adaptation (15K-40K), reasonable circuit board design, low coefficient of temperature change, and there will be 7*24 hours of aging test before delivery.The mains electricity is converted into high-frequency high-voltage alternating current, which is transmitted to the ultrasonic transducer. Ultrasonic transducer is equivalent to energy conversion device, it can convert the input electrical energy into mechanical energy, that is, ultrasonic. The ultrasonic transducer moves back and forth in the longitudinal direction, and the frequency of the stretching motion is equal to the frequency of the high-frequency alternating current supplied by the driving power supply.

Cake cutter vs. ultrasonic cutting machine in the context of traditional manufacturing methods

- Cost-effectiveness

Difference between ultrasonic cutting machines and regular cutting machines: cost-effectiveness. These machines require minimal maintenance and have a longer lifespan than traditional cutting methods. In addition, the ultrasonic cutting process does not require the use of blades or other consumables, eliminating the need for frequent replacements. In the long run, this reduces operating costs and increases business savings. Ultrasonic cutting technology is quite different from general cutting and is able to guarantee accurate cutting without damaging the product being cut, preserving the integrity of the cut object to the greatest extent possible. Ultrasonic cutting knife is carried out through the drive system with precise and fast servo drive, the whole system can speed up the progress of cutting, while making the ultrasonic cutting machine consumes less energy. Integrating the use of ultrasonic cutters into industrial processes can maximize time savings, increase productivity and improve productivity.

- Improved Safety

Ultrasonic cutters offer a higher level of safety than traditional cutting methods. The absence of sharp blades reduces the risk of accidents and injuries in the workplace. In addition, the cutting process generates minimal heat, eliminating the possibility of burns or damage to the material being cut. This makes ultrasonic cutters a safer choice for operators and ensures a safe work environment.

- Precision Cutting

Ultrasonic cutters offer superior cutting precision resulting in clean and accurate cuts. Ultrasonic vibration creates high frequency motion that allows for intricate and detailed cuts, even with complex shapes and patterns. This accuracy is especially beneficial in industries that require complex designs or tight tolerances, resulting in more precise cuts than ordinary cutting machines, which can cut down to 1mm. The quality of cut that can be achieved with an ultrasonic cutting machine is much better than that of conventional tool cutting. Ultrasonic cutters are extremely accurate and can better meet the various cutting constraints in industrial environments. Ultrasonic cutting knives are small, convenient, and flexible, and can be combined with automated equipment to achieve the purpose of cutting food products at any angle to maximize the ideal food form.

FAQ

What are your main products and their application?

Our factory Wanli manufactures the automatic ultrasonic food cutting machine bakery equipment (cake depositor machine, cake spreading machine, cake decorating machine, cake depanner machine) with high quality & very competitive price for 10 years in China. If you have any special request for the machine, we can customize it. We are in good position not only to supply you high quality machinery, but also the excellent after sales service. Well-trained engineers will offer you any technical support. If you have any purchase of food production machinery, please feel free to contact me. Let’s talk more in details.

About machines and services?

If you have any questions (machine installation, use method, parts replacement, maintenance, precautions, etc.) after receiving the machine or during use, please feel free to contact me, we will provide the best solution. 24 hours online service to solve any problem. Your satisfaction is our pursuit. Sincerely hope to cooperate with us.

What are your main products and their application?

Our factory Wanli manufactures the automatic ultrasonic food cutting machine bakery equipment (cake depositor machine, cake spreading machine, cake decorating machine, cake depanner machine) with high quality & very competitive price for 10 years in China. If you have any special request for the machine, we can customize it.

We are in good position not only to supply you high quality machinery, but also the excellent after sales service. Well-trained engineers will offer you any technical support.

If you have any purchase of food production machinery, please feel free to contact me. Let’s talk more in details.

Are you a manufacturer or a trading company?

Our factory is a professional manufacturer of ultrasonic food cutting machine, has a history of more than ten years. We specialize in manufacturing high-tech food machinery to provide new production mode for food enterprises. Our machines are of good quality. Our factory has produced thousands of machines. We can customize according to customers’ requirements and conduct in-depth communication with customers. In order to provide customers with better needs, we have a special department to serve you.After fully understanding the customer’s needs, our engineers will design the drawings and modify them to the customer’s satisfaction. The production of the machine is carried out in full accordance with the drawings. Before the machine leaves the factory, we will take videos and measure the size for the customer to confirm.

What is the after-sales service of your company?

Our machines are inspected and tested before delivery to make sure there are no problems with the machines themselves.

If the machine has problems under incorrect operation.

- Improper operation, we will solve all use problems through video calls.

- If there is a problem with the machine parts, we will send you the parts to ensure the normal use of the machine.

- Is there a warranty?

One year warranty. Frankly speaking, the quality of our machines is very stable. Machines are tested before they leave the factory to make sure they arrive at your address in top condition. In addition, we provide a full set of manuals and operating instructions in English to help our customers use the machines better. During your use, if you have any questions, we can make a video call at any time.

What is the difference with other domestic brands?

We don’t just sell machines, we pay more attention to after-sales service. We always believe that the customer’s word of mouth is the best advertising. We want to really help our customers use these machines and bring growth to their business.” You can look at the feedback from our customers, the facts speak for themselves.

What are your advantages compared to your competitors?

With rich industry experience and strict product quality control system, we offer.

- High quality and stable machines

- Excellent customer service and after-sales service with quick response

- Fast and timely delivery

Can you explain the whole transaction process to me?

- Sign the contract.

- Arrange 30% deposit to confirm the order.

- Factory arranges production.

- Testing and inspection of the machine before shipment.

- Inspection by customer or third party organization through online or on-site testing.

- Arrange final payment before shipment.

What information should I tell you if I want to get a WANLI bakery equipment quote?

- Can you show us the picture of your products?

- Can you provide us your baking tray drawings or photos?

- Is the product directly connected to the production line?

- Can you tell us the material of your products?

What are the advantages of your blades?

Wanli Ultrasonic blade: the materials of our ultrasonic blade is from Germany, It is made of TC11D, Titanium Alloy. Our warranty is 1 year, if operate correctly, it would be no problem even within 5 years.

How to make Order?

- Customer send us an inquiry.

- Confirm machine type, order quantity, price, lead time, payment term etc.

- Our sales send the Proforma Invoice with company seal.

- Customer make the payment for deposit and send us Bank receipt.

- Inform the clients that we have got the payment,and will arrange the production according to your request, inform the estimated time

- Production products photos will send to you for approval.

- Clients make payment for balance and Ship the goods .

- Order is finished when you receive the goods and satisfy with them .

- Feedback to us about Quality , Service, Market Feedback & Suggestion.And we can do better

What’s the principle of ultrasonic cutting?

Wanlisonic offers high quality ultrasonic food cutting components, including ultrasonic generators, transducers, guillotines and slitters.

Ultrasonic food processing involves a vibrating knife (guillotine) producing a nearly frictionless surface that minimizes buildup on the blade surface. The ultrasonic blades cleanly cuts sticky products and inclusions such as nuts, raisins & morsels without displacement. Ultrasonic cutting is used by many of the world’s largest and most prestigious food producers.

This ultrasonic cutting system emits some radiation?

No. Ultrasonic cake cutting machine is ultrasonic generator produce the mechanical energy of vibration more than 20000 times per second to the cutting blade, it cut the food material by local vibration very quickly, the friction on the food surface is very small,the food can apart by the titanium blade very quickly, to achieve the aim of cutting materials requirements. What ‘s more, our machine also get the patent for the food level, see attached about our patent copy for our Ultrasonic Food Cutting Machine.

How does the ultrasonic cake cutting machine achieve quick and precise positioning of products?

Servo control, that is, human activities that control the generated motion and the motion of objects to meet a certain purpose. The so-called servo control refers to the effective control of the changes in the position, speed and acceleration of the object movement. This kind of control has been popularized in various fields. Servo control system refers to a feedback control system used to accurately follow or reproduce a process.

After-sales Service

According to spare parts, the most important part is the ultrasonic unit, it will debug one week before the shipment to make sure .The blade have one year guarantee. It is made of TC11D, Titanium Alloy. If operated correctly, it could take very very long, remember not to cut hard goods, and operate it correctly, train the operator first. If not clear, ask us first, and I will ask our engineer to teach you.

We will produce the machine according to the customer’s requirements, each machine is customized. We strictly follow the customer’s requirements to produce according to the drawings confirmed by the customer. Our engineers will produce the machine precisely to ensure the quality of the machine. After the machine finishes production, we will take a video for customer inspection.

The process of machine inspection

First of all, we started by checking the appearance of the ultrasonic candy cutting machine. Check whether the machine is the same as the drawing, whether there is any wear and tear on the surface of the machine, and measure the machine to measure whether the various data of the machine meets the requirements. We did some checking on the machine and confirmed that the appearance of the ultrasonic cake cutting machine was perfect.

Secondly, check the data on the ultrasonic candy cutting machine’s display, as the machines are customized and each machine is different. Our customization options ensure that the customer receives an ultrasonic cake cutting machine that exactly meets their business goals. Take photos and records, and send them to the customer to check.

Finally, let the machine operate. Engineers check whether the running process is normal or not, take a video of the machine running, and send it to the customer. Take a video of the machine without product cutting and send it to the customer to check. Then shoot the video of the machine cutting the cake for the customer to confirm.

After the ultrasonic cake cutting machine arrives at the customer’s factory, the customer can operate it according to the instruction manual sent by us. Our ultrasonic cake cutting machine does not need to be installed and you will be able to use the machine once you receive it. If the customer does not know how to use the machine, we will guide the customer one by one. We usually use video with the customer to guide until the machine can be used normally.

We also regularly greet customers who have purchased our machines, asking how they are using them and what feedback they have. And summarize this feedback to better optimize our machines. To provide customers with a better experience.

In conclusion

Ultrasonic cake cutting machines provide numerous advantages that make them a valuable asset in various industries. From increased productivity and cost-effectiveness to improved safety and versatility, these machines offer a range of benefits. The high-speed cutting capabilities, minimal maintenance requirements, and enhanced precision make ultrasonic cutting machines an ideal choice for businesses looking to optimize their cutting processes. By investing in ultrasonic cutting technology, companies can improve their overall efficiency, reduce costs, and deliver high-quality products to their customers. Ultrasonic cutting knives are being widely used in various bakery food industries and are one of the hottest food processing machines available. Due to the advantages of the ultrasonic blade itself, coupled with the development of technology, it makes more and more people know about its existence. Our factory Wanli specializes in the research, development, and production of ultrasonic cutting equipment, There are individual cutting machines and equipment that can link the production of the assembly line. Customers from all over the world are always welcome to inquire about ultrasonic food-cutting machines.

Related Products