Introduction

Imagine a bakery where every slice of cake is perfectly uniform, clean, and precise. The secret behind this dream-like scenario? The ultrasonic cake cutting machine. This technological marvel has revolutionized the way bakeries operate, bringing unparalleled precision and efficiency to the art of cake cutting.

What is an Ultrasonic Cake Cutting Machine?

An ultrasonic cake cutting machine is a device that uses high-frequency ultrasonic vibrations to cut through cakes and other bakery products. Unlike traditional cutting methods that rely on sharp blades and manual effort, ultrasonic machines use sound waves to create a clean, precise cut. This technology minimizes the mess and maximizes the quality of each slice.

Key Features of Ultrasonic Cake Cutting Machines

Ultrasonic Technology

At the heart of these machines is ultrasonic technology, which employs sound waves at frequencies higher than the human hearing range. These waves create rapid vibrations that allow the blade to glide through cakes with minimal resistance, producing a clean cut every time.

Precision Cutting

One of the standout features of ultrasonic cake cutting machines is their precision. The ultrasonic blade can cut through cakes with intricate designs and delicate textures without distorting the shape or causing crumbling. This precision is particularly valuable for high-end bakeries and pastry chefs who need to maintain the aesthetic integrity of their creations.

Speed and Efficiency

Ultrasonic cutting machines are significantly faster than manual cutting methods. The speed and efficiency of these machines help bakeries meet high demand during peak times, reducing wait times and increasing customer satisfaction.

The Self-Cleaning Function

How It Works

The self-cleaning function is a game-changer for busy bakeries. It works by automatically cleaning the blade using ultrasonic vibrations and a cleaning solution. This process removes any residue or build-up on the blade, ensuring it remains sharp and effective.

Benefits of Self-Cleaning Mechanism

The self-cleaning function reduces the time and effort required for manual cleaning, allowing bakery staff to focus on other tasks. It also ensures that the blade remains hygienic, which is crucial in maintaining food safety standards.

Maintenance Reduction

Regular cleaning and maintenance are essential for any cutting machine, but the self-cleaning function significantly reduces the maintenance burden. This leads to fewer downtimes and prolonged machine lifespan.

The Non-Sticky Blade

Composition and Material

The non-sticky blade is typically made from high-grade stainless steel with a special coating that prevents cake residues from sticking. This coating is food-safe and durable, ensuring consistent performance over time.

Advantages Over Traditional Blades

Traditional blades often require frequent cleaning and can struggle with sticky or gooey cakes. The non-sticky blade eliminates these issues, providing a smooth and clean cut every time.

Impact on Cutting Quality

With a non-sticky blade, each slice comes out clean and uniform, which is essential for presentation and customer satisfaction. This feature also reduces waste, as there are no remnants left on the blade to contaminate subsequent cuts.

Advantages of Using Ultrasonic Cake Cutting Machines

Consistency and Uniformity

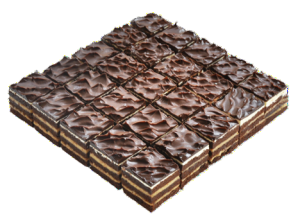

Ultrasonic cake cutting machines ensure that every slice is consistent in size and shape. This uniformity is crucial for portion control and professional presentation.

Reduced Waste

The precision and efficiency of ultrasonic cutting result in less waste. Every cut is clean, leaving no crumbs or broken pieces behind. This not only saves money but also ensures that every part of the cake can be sold.

Enhanced Hygiene

The self-cleaning function and non-sticky blade significantly enhance the hygiene of the cutting process. This is particularly important in the food industry, where cleanliness is paramount.

Applications in Various Bakery Products

Cakes

Whether it’s a simple sponge cake or an elaborate multi-layered creation, ultrasonic cutting machines can handle it all. The precision ensures that each slice is perfect, maintaining the integrity of the cake’s design.

Pastries

Pastries often have delicate layers and fillings that can be easily damaged by traditional cutting methods. Ultrasonic machines make clean cuts through pastries, preserving their structure and presentation.

Cheesecakes

Cheesecakes are notoriously difficult to cut due to their creamy texture. Ultrasonic cutting machines glide through cheesecakes effortlessly, producing neat slices without smudging or crumbling.

Technical Specifications

Power Requirements

Ultrasonic cake cutting machines typically require a standard electrical outlet for power. The exact power requirements can vary depending on the model and its features.

Blade Dimensions

The blades used in these machines come in various sizes to accommodate different types of cakes and pastries. Choosing the right blade size ensures optimal performance and cutting quality.

Operational Settings

These machines offer various operational settings, allowing users to adjust the cutting speed, blade frequency, and other parameters. This flexibility ensures that the machine can handle a wide range of bakery products.

Ease of Use and User Interface

Intuitive Controls

Modern ultrasonic cake cutting machines are designed with user-friendly interfaces. Intuitive controls make it easy for operators to set up and run the machine, even with minimal training.

Training and Setup

Manufacturers often provide training and setup assistance to ensure that bakery staff can operate the machine efficiently. This support is invaluable in helping bakeries get the most out of their investment.

Cost and Investment

Initial Cost

The initial cost of an ultrasonic cake cutting machine can be significant. However, this investment is often justified by the long-term benefits it provides in terms of efficiency, consistency, and reduced waste.

Long-term Savings

While the upfront cost is high, the long-term savings from reduced waste, lower maintenance, and increased productivity can make ultrasonic cake cutting machines a cost-effective solution for bakeries.

Customer Testimonials and Case Studies

Success Stories

Many bakeries have reported significant improvements in efficiency and product quality after adopting ultrasonic cake cutting machines. Success stories highlight the transformative impact of this technology.

Real-world Applications

Case studies provide real-world examples of how ultrasonic cake cutting machines have been implemented in various bakery settings. These examples demonstrate the versatility and effectiveness of the technology.

Common Issues and Troubleshooting

Like any technology, ultrasonic cake cutting machines can encounter issues. Common problems include blade wear and alignment issues. Troubleshooting guides and manufacturer support can help resolve these issues quickly.

Manufacturer Support

Reliable manufacturer support is essential for ensuring that any issues are promptly addressed. This support can include troubleshooting assistance, maintenance services, and replacement parts.

Future Innovations in Ultrasonic Cutting Technology

Emerging Trends

The field of ultrasonic cutting technology is continually evolving. Emerging trends include improvements in blade materials, more efficient power consumption, and enhanced user interfaces.

Predicted Developments

Future developments may include even more advanced self-cleaning functions, integration with other bakery equipment, and increased automation capabilities. These innovations will further enhance the efficiency and versatility of ultrasonic cake cutting machines.

Conclusion

Ultrasonic cake cutting machines with self-cleaning functions and non-sticky blades represent a significant advancement in bakery technology. Their precision, efficiency, and hygiene benefits make them an invaluable tool for modern bakeries. By investing in this technology, bakeries can enhance their product quality, reduce waste, and increase overall productivity.

FAQs

- How does ultrasonic cutting work?

- Ultrasonic cutting uses high-frequency sound waves to create rapid vibrations in the blade, allowing it to cut through cakes cleanly and precisely.

- Can it cut through all types of cakes?

- Yes, ultrasonic cutting machines can handle a variety of cakes, including those with delicate textures and intricate designs.

- What is the lifespan of the non-sticky blade?

- The lifespan of a non-sticky blade varies depending on usage, but with proper maintenance, it can last for several years.

- Is the machine safe to use?

- Yes, ultrasonic cake cutting machines are designed with safety features to ensure safe operation. Proper training and adherence to guidelines further enhance safety.

- How often does the self-cleaning function need to be activated?

- The self-cleaning function can be activated as needed, typically after every use or when cutting multiple cakes in succession to maintain optimal blade performance and hygiene.