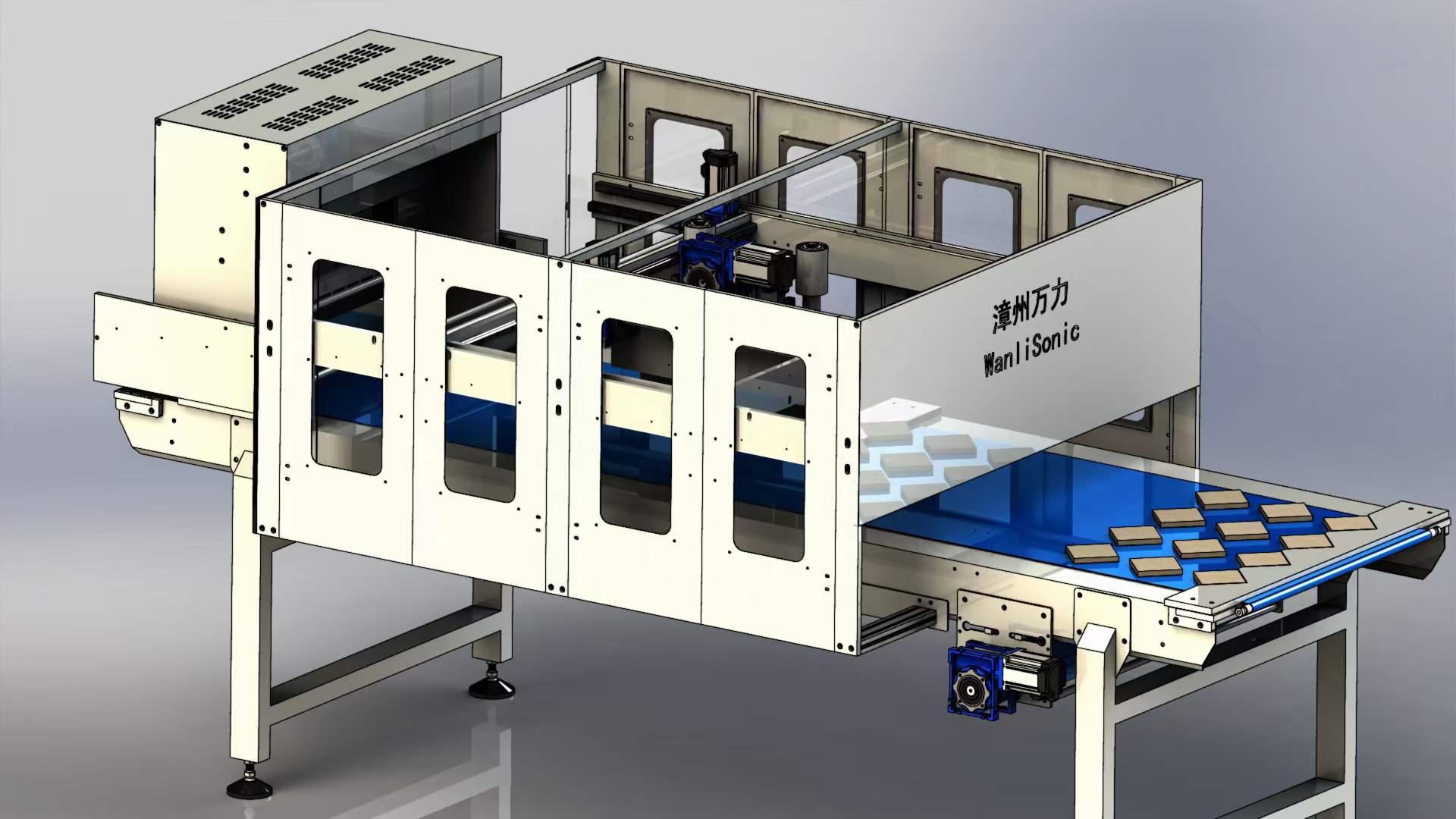

Ultrasonic Cheese Cutting Machine With Double-Wave Blade

Cheese cutting may seem simple, but in industrial settings, precision is critical to maintaining quality, reducing waste, and increasing productivity. Enter the ultrasonic cheese cutting machine with double-wave blade, an innovation that’s transforming the cheese industry. This cutting-edge technology delivers unparalleled precision, ensuring that each slice of cheese is uniform, clean, and perfectly portioned. So, what makes this machine a standout? Let’s dive into the details.

Understanding Ultrasonic Technology

Ultrasonic technology harnesses high-frequency sound waves to perform precise cutting tasks. In cheese cutting, this technology minimizes friction by using vibrations that move a blade thousands of times per second. This makes it possible to slice through even the softest or stickiest cheeses without causing deformities or damage to the product. The result? Perfect slices, every time.

What is a Double-Wave Blade?

The double-wave blade is the heart of this innovative machine. Unlike traditional blades, which can struggle with varying cheese textures, the double-wave blade’s unique structure allows it to handle soft, hard, and even specialty cheeses with ease. Its design optimizes the cutting process by reducing friction and minimizing adhesion, so the cheese doesn’t stick to the blade.

Advantages of Ultrasonic Cheese Cutting Machines

Enhanced Precision and Accuracy

One of the biggest advantages of ultrasonic cutting technology is its precision. Ultrasonic machines use fine-tuned sound waves to guide the blade with impeccable accuracy, resulting in consistent and uniform cuts.

Reduced Waste and Improved Yield

Traditional cutting methods can often lead to uneven slices, resulting in significant waste. However, with ultrasonic technology, waste is minimized because the cuts are precise and uniform, improving overall yield.

Versatility Across Different Cheese Types

Whether you’re slicing through soft, creamy brie or a hard block of cheddar, the ultrasonic cheese cutting machine handles it all. Its versatility makes it a valuable asset in any cheese production environment.

Consistent, Clean Cuts Every Time

Say goodbye to ragged edges and misshapen slices. With ultrasonic technology, each cut is clean and smooth, ensuring the cheese looks as good as it tastes.

How the Double-Wave Blade Enhances Cutting Efficiency

The double-wave blade is designed to enhance the efficiency of the cutting process. Its waved edges reduce friction as it cuts, allowing it to glide through cheese with minimal resistance. This not only ensures cleaner cuts but also extends the lifespan of the blade by reducing wear and tear.

Applications of Ultrasonic Cheese Cutting Machines

Ultrasonic cheese cutting machines are used across a variety of industries, from large-scale cheese production to specialty artisan cheese makers. They’re also valuable in catering and restaurant settings, where presentation is key, and precision cuts can make all the difference.

Types of Cheese Best Suited for Ultrasonic Cutting

Soft Cheeses

Soft cheeses like brie, camembert, and blue cheese can be difficult to cut cleanly due to their high moisture content. Ultrasonic technology makes it possible to slice through these delicate cheeses without squishing or distorting them.

Hard Cheeses

Cheddar, gouda, and parmesan can be quite tough on traditional blades, but the ultrasonic machine handles them with ease. The precision cutting process ensures that even these dense cheeses are sliced with accuracy.

Specialty Cheeses

Artisan cheeses often come in irregular shapes and sizes. The ultrasonic cheese cutting machine with a double-wave blade ensures that even the most unique cheeses are sliced uniformly, preserving their aesthetic appeal.

Comparing Ultrasonic Cutting Machines with Traditional Cheese Cutters

Performance Comparison

Traditional cheese cutters rely on manual force, which can result in uneven cuts and wasted product. In contrast, ultrasonic machines use controlled vibrations, leading to more consistent slices with minimal waste.

Cost-Effectiveness

While the initial investment in ultrasonic technology may be higher than traditional cutters, the long-term savings in reduced waste and increased productivity make it a cost-effective solution.

Maintenance and Durability

Ultrasonic machines require minimal maintenance compared to traditional cutters. The double-wave blade is designed for durability, meaning fewer replacements and lower maintenance costs over time.

Key Features of the Ultrasonic Cheese Cutting Machine with Double-Wave Blade

This machine comes equipped with several features that make it stand out:

- User-Friendly Interface:Easy to operate with minimal training.

- Customizable Settings:Adjust for different cheese textures to achieve the perfect slice every time.

- Safety Features:Built-in safeguards ensure safe operation, even in high-speed production environments.

How to Choose the Right Ultrasonic Cheese Cutting Machine

When choosing an ultrasonic cheese cutting machine, it’s essential to consider your production needs. For industrial use, look for machines with higher capacity and durability. Small-scale producers should focus on machines that offer versatility and ease of use.

The Future of Cheese Cutting Technology

The future of cheese cutting lies in automation and precision. Ultrasonic technology is paving the way for more efficient production processes, and we can expect to see even more innovations in this field in the coming years.

Common Misconceptions about Ultrasonic Cheese Cutting Machines

There are a few myths about ultrasonic cutting machines, such as the idea that they are too expensive for small producers or that they require constant maintenance. In reality, these machines are designed to be both cost-effective and low-maintenance, making them accessible to a wide range of producers.

Sustainability and Ultrasonic Cheese Cutting

Ultrasonic cheese cutting machines are also eco-friendly. They use less energy compared to traditional machines and significantly reduce food waste, making them a more sustainable option for cheese producers.

Conclusion

The ultrasonic cheese cutting machine with double-wave blade is revolutionizing the cheese industry. Its ability to deliver precise, clean cuts across a variety of cheese types, combined with its efficiency and sustainability, make it an invaluable tool for any cheese producer. Whether you’re an industrial manufacturer or a small artisan maker, investing in ultrasonic technology could be a game changer for your business.

FAQs

- How does ultrasonic technology work for cutting cheese?

Ultrasonic technology uses high-frequency vibrations to reduce friction and allow the blade to slice through cheese cleanly and precisely. - Is the double-wave blade suitable for all cheese types?

Yes, the double-wave blade is designed to handle both soft and hard cheeses, ensuring consistent cuts across various textures. - What maintenance is required for an ultrasonic cheese cutting machine?

These machines require minimal maintenance, with occasional blade sharpening and standard machine checks. - Can small-scale cheese makers benefit from this technology?

Absolutely! Small producers can benefit from the precision, reduced waste, and ease of use that ultrasonic machines offer. - How does this technology improve overall cheese quality?

By ensuring clean, consistent cuts, ultrasonic technology helps maintain the cheese’s shape, texture, and visual appeal, leading to higher quality products.