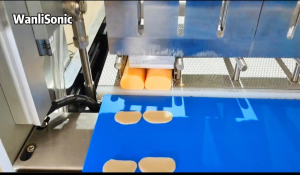

Ultrasonic Prawn Crisps Cutting Machine

Introduction to Ultrasonic Cutting Technology

Ultrasonic cutting technology is a revolutionary advancement in the food processing industry. Utilizing high-frequency sound waves, this technology allows for precise and efficient cutting of various food products, including prawn crisps. The ultrasonic prawn crisps cutting machine is a specialized piece of equipment designed to handle this task with remarkable accuracy and consistency. Here’s an overview of how it works and its benefits:

How Ultrasonic Cutting Works

The Basics of Ultrasonic Technology

Ultrasonic cutting involves the use of high-frequency sound waves, typically in the range of 20 kHz to 40 kHz. These sound waves are generated by an ultrasonic transducer, which converts electrical energy into mechanical vibrations. These vibrations are then transmitted to a cutting blade, which oscillates at an ultrasonic frequency.

The Cutting Process

When the ultrasonic blade comes into contact with the prawn crisps, the high-frequency vibrations create a rapid series of small, precise movements. These movements produce a cutting action that is both smooth and clean, minimizing the risk of tearing or crushing the delicate crisps. The ultrasonic vibrations also generate heat, which helps to cut through the crisps with minimal resistance.

Components of the Ultrasonic Prawn Crisps Cutting Machine

- Ultrasonic Generator: Converts electrical energy into high-frequency ultrasonic energy.

- Transducer: Converts the ultrasonic energy into mechanical vibrations.

- Cutting Blade: The component that directly contacts and cuts the prawn crisps.

Benefits of Using an Ultrasonic Prawn Crisps Cutting Machine

Precision and Consistency

One of the primary benefits of using an ultrasonic prawn crisps cutting machine is the high level of precision it offers. The ultrasonic vibrations ensure that each cut is clean and accurate, resulting in uniformly sized crisps. This consistency is crucial for maintaining product quality and meeting industry standards.

Enhanced Productivity

Faster Processing Times

An ultrasonic prawn crisps cutting machine significantly enhances productivity by reducing processing times. The high-frequency vibrations enable faster cutting speeds compared to traditional methods. This efficiency allows manufacturers to increase their output without compromising on quality.

Reduced Downtime

Ultrasonic cutting machines are designed to be durable and require minimal maintenance. The reduced downtime for maintenance and repairs means that production lines can run continuously, further boosting productivity. This reliability is essential for meeting tight production schedules and ensuring timely deliveries.

Improved Product Quality

Minimized Waste

The precision of ultrasonic cutting minimizes waste by ensuring each prawn crisp is cut to the exact specifications. This accuracy reduces the amount of product that is discarded due to irregular shapes or sizes. As a result, manufacturers can maximize their use of raw materials, leading to cost savings and a more sustainable production process.

Enhanced Appearance and Texture

Ultrasonic cutting technology preserves the appearance and texture of prawn crisps. The clean cuts prevent the edges from becoming crushed or frayed, maintaining the visual appeal of the final product. Additionally, the uniform thickness of each crisp ensures a consistent texture, enhancing the overall eating experience for consumers.

Versatility and Flexibility

Adaptability to Different Shapes and Sizes

Ultrasonic prawn crisps cutting machines are highly versatile and can be easily adapted to cut prawn crisps into various shapes and sizes. This flexibility allows manufacturers to create a diverse range of products to meet different market demands and consumer preferences.

Customization Options

Manufacturers can customize the cutting parameters of ultrasonic machines to achieve specific product characteristics. By adjusting the frequency and amplitude of the ultrasonic vibrations, they can fine-tune the cutting process to produce crisps with unique textures and appearances. This level of customization is invaluable for differentiating products in a competitive market.

Cost Efficiency

Reduced Labor Costs

The automation provided by ultrasonic cutting machines reduces the need for manual labor. Fewer workers are required to operate the machines, leading to significant labor cost savings. This reduction in labor costs can be redirected towards other areas of the business, such as research and development or marketing.

Energy Efficiency

Ultrasonic cutting machines are known for their energy efficiency. They consume less power compared to traditional cutting methods, leading to lower energy bills. This energy efficiency not only reduces operational costs but also contributes to a smaller carbon footprint, aligning with sustainable production practices.

Safety and Hygiene

Enhanced Safety Features

Ultrasonic prawn crisps cutting machines are equipped with advanced safety features to protect operators. The machines are designed to minimize the risk of accidents, with automatic shut-off mechanisms and protective guards. This focus on safety ensures a safer working environment and reduces the likelihood of workplace injuries.

Hygienic Cutting Process

The ultrasonic cutting process is inherently hygienic. The high-frequency vibrations generate heat, which can help to sterilize the cutting blade. This sterilization reduces the risk of contamination, ensuring that the prawn crisps remain safe for consumption. Maintaining high hygiene standards is essential for complying with food safety regulations and protecting consumer health.

Applications of Ultrasonic Cutting in the Food Industry

Cutting Other Snack Foods

In addition to prawn crisps, ultrasonic cutting technology is widely used for other snack foods, such as potato chips, nachos, and vegetable crisps. The ability to produce clean, uniform cuts without damaging the delicate structure of these snacks makes ultrasonic cutting an ideal choice for these products.

Slicing Baked Goods

Ultrasonic cutting machines are also commonly used for slicing baked goods, including cakes, bread, and pastries. The precision of ultrasonic cutting ensures that these products are sliced evenly, without causing crumbling or distortion.

Portioning Confectionery Products

Confectionery items, such as chocolates, nougats, and candies, can also benefit from ultrasonic cutting. The technology allows for precise portioning, ensuring that each piece is of uniform size and weight. The ultrasonic vibrations reduce the resistance encountered when cutting through frozen materials, resulting in smooth, clean cuts.

Choosing the Right Ultrasonic Cutting Machine

Factors to Consider

When selecting an ultrasonic prawn crisps cutting machine, several factors should be taken into account:

- Cutting Speed: Ensure that the machine can meet the production requirements of your facility.

- Blade Size and Shape: Choose a blade that is suitable for the specific shape and size of your prawn crisps.

- Maintenance Requirements: Consider the ease of maintenance and cleaning to ensure minimal downtime.

- Compatibility with Other Equipment: Ensure that the machine can be integrated seamlessly into your existing production line.

Conclusion

The ultrasonic prawn crisps cutting machine represents a significant advancement in food processing technology. By leveraging high-frequency ultrasonic vibrations, this machine offers unparalleled precision, reduced waste, improved hygiene, and enhanced product appearance. Its versatility extends beyond prawn crisps, making it a valuable asset for various applications in the food industry. Investing in an ultrasonic cutting machine can lead to increased efficiency, cost savings, and higher product quality, ultimately giving manufacturers a competitive edge in the market.