Ultrasonic Rectangle Cake Cutting Machine

Introduction

In today’s fast-paced food industry, efficiency and precision are paramount. Enter the ultrasonic rectangle cake cutting machine, a revolutionary tool transforming how bakeries and large-scale food production facilities operate. This advanced technology offers unparalleled benefits, ensuring clean, precise cuts that traditional methods struggle to achieve. Let’s delve into what makes these machines so essential and explore their impact on the food industry.

What is an Ultrasonic Rectangle Cake Cutting Machine?

Definition and Basic Functionality

An ultrasonic rectangle cake cutting machine uses high-frequency ultrasonic waves to cut through cakes and other baked goods. The ultrasonic vibrations reduce friction, resulting in smooth, precise cuts without crushing or crumbling the product.

Key Components

- Ultrasonic Generator: Converts electrical energy into high-frequency ultrasonic waves.

- Transducer: Transfers ultrasonic waves to the cutting blade.

- Cutting Blade: Vibrates at ultrasonic frequencies to cut through products cleanly.

How Ultrasonic Technology Works

Principles of Ultrasonic Cutting

Ultrasonic cutting involves converting electrical energy into mechanical vibrations through an ultrasonic generator. These vibrations are transferred to the cutting blade, which oscillates at high frequencies. The rapid motion reduces the contact area between the blade and the product, minimizing resistance and enabling precise cuts.

Benefits Over Traditional Cutting Methods

- Reduced Product Waste: Minimal crumbling and deformation.

- Enhanced Precision: Accurate cuts with clean edges.

- Time Efficiency: Faster cutting process compared to conventional methods.

Types of Ultrasonic Cutting Machines

Manual vs. Automatic

- Manual Machines: Operated by hand, suitable for small-scale operations.

- Automatic Machines: Computer-controlled for large-scale production, ensuring consistent cuts and higher throughput.

Single-Blade vs. Multi-Blade Systems

- Single-Blade Systems: Ideal for custom and intricate cuts.

- Multi-Blade Systems: Efficient for high-volume production with uniform cuts.

Advantages of Ultrasonic Rectangle Cake Cutting Machines

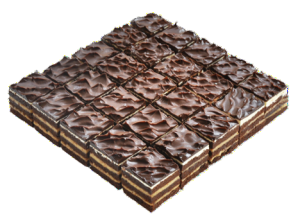

Precision and Clean Cuts

The ultrasonic blade’s rapid vibrations allow for precise, clean cuts, reducing the risk of damaging delicate cakes and other baked goods.

Increased Efficiency

Ultrasonic cutting machines significantly speed up the cutting process, making them ideal for high-demand environments like large bakeries and food production facilities.

Versatility in Cutting Various Products

These machines can handle a variety of products beyond cakes, including pastries, bread, and even sticky or layered items like cheesecakes and mousse cakes.

Applications in the Food Industry

Bakeries

Ultrasonic cutters are a staple in modern bakeries, ensuring consistent, aesthetically pleasing cake slices that enhance customer satisfaction.

Confectioneries

Confectioneries benefit from the precision and versatility of ultrasonic cutters, which can handle a wide range of products, from chocolates to nougats.

Large-Scale Food Production

For large-scale food producers, ultrasonic cutters offer the efficiency needed to maintain high production rates while ensuring product quality.

Choosing the Right Ultrasonic Cake Cutting Machine

Factors to Consider

- Production Volume: Choose a machine that matches your production needs.

- Product Variety: Ensure the machine can handle the range of products you produce.

- Space and Budget: Consider the machine’s footprint and your budget constraints.

Customization Options

Many manufacturers offer customizable options, allowing you to tailor the machine to your specific needs, including blade types and cutting patterns.

Maintenance and Care Tips

Regular Cleaning Procedures

Keeping the ultrasonic cutter clean is essential for maintaining its efficiency and longevity. Regularly clean the blade and other components as per the manufacturer’s guidelines.

Troubleshooting Common Issues

- Inconsistent Cuts: Check for blade wear or improper settings.

- Noise or Vibration: Ensure the machine is properly maintained and parts are securely fastened.

Cost and Investment Considerations

Initial Investment

While ultrasonic cutters represent a significant upfront investment, their efficiency and precision can lead to substantial long-term savings.

Long-Term Cost Efficiency

Reduced product waste, lower labor costs, and enhanced production rates contribute to the long-term cost efficiency of ultrasonic cutting machines.

Future Trends in Ultrasonic Cake Cutting

Technological Advancements

Advancements in ultrasonic technology, such as improved blade materials and smarter control systems, continue to enhance the performance and capabilities of these machines.

Emerging Market Demands

As consumer demand for high-quality, aesthetically pleasing baked goods grows, the adoption of ultrasonic cutting technology is likely to increase.

Comparing Ultrasonic Cutting with Other Cutting Methods

Mechanical Cutting

Mechanical cutters are less precise and can cause more product waste due to crumbling and deformation.

Laser Cutting

While laser cutters offer precision, they are typically more expensive and less suitable for cutting delicate food products.

Environmental Impact

Energy Efficiency

Ultrasonic cutters are energy-efficient, consuming less power compared to many traditional cutting methods.

Waste Reduction

By minimizing product waste, ultrasonic cutting machines contribute to more sustainable production practices.

Conclusion

Ultrasonic rectangle cake cutting machines represent a significant advancement in food production technology. Their precision, efficiency, and versatility make them invaluable assets for bakeries, confectioneries, and large-scale food producers. As technology continues to evolve, these machines will likely become even more integral to the industry, driving quality and innovation forward.

FAQs

1. What types of cakes can be cut with an ultrasonic rectangle cake cutting machine?

Ultrasonic cutting machines can handle a variety of cakes, including layered, mousse, and even sticky cakes like cheesecakes.

2. How does ultrasonic cutting reduce waste?

The high-frequency vibrations of the ultrasonic blade result in clean cuts with minimal crumbling, significantly reducing product waste.

3. Are ultrasonic cutting machines difficult to maintain?

No, with regular cleaning and proper care, ultrasonic cutting machines are relatively easy to maintain.

4. Can ultrasonic cutters be customized?

Yes, many manufacturers offer customization options to tailor the machine to specific production needs.

5. Is the initial investment in an ultrasonic cutting machine worth it?

Yes, despite the upfront cost, the efficiency, precision, and long-term savings make it a worthwhile investment for many food producers.