Ultrasonic Swiss Roll Cutting Machine

Introduction

Ever wondered how those perfectly sliced Swiss rolls get their flawless cuts? Enter the ultrasonic Swiss roll cutting machine. This innovative piece of equipment is revolutionizing the food industry, ensuring each slice of your favorite pastry is just right. But what exactly is an ultrasonic Swiss roll cutting machine, and why is it so important? Let’s dive in and explore!

History of Ultrasonic Cutting Technology

Evolution of Ultrasonic Technology

Ultrasonic technology isn’t exactly new; it’s been around for decades, primarily in medical and industrial fields. However, its application in food processing is a relatively recent development. Initially used for non-destructive testing and medical imaging, ultrasonic technology has found its way into our kitchens, making food processing more efficient and precise.

Application in Food Processing

The transition of ultrasonic technology into food processing was a game-changer. It allowed for precise cuts without compromising the integrity of delicate food items like Swiss rolls, cakes, and cheeses. This technology has been embraced by bakers and food manufacturers worldwide, streamlining production and enhancing product quality.

How Ultrasonic Cutting Works

The Science Behind Ultrasonic Cutting

Ultrasonic cutting uses high-frequency sound waves to create rapid vibrations in a cutting blade. These vibrations reduce friction, allowing the blade to slice through food items smoothly and cleanly. Imagine a knife cutting through butter—that’s the kind of ease ultrasonic cutting aims for.

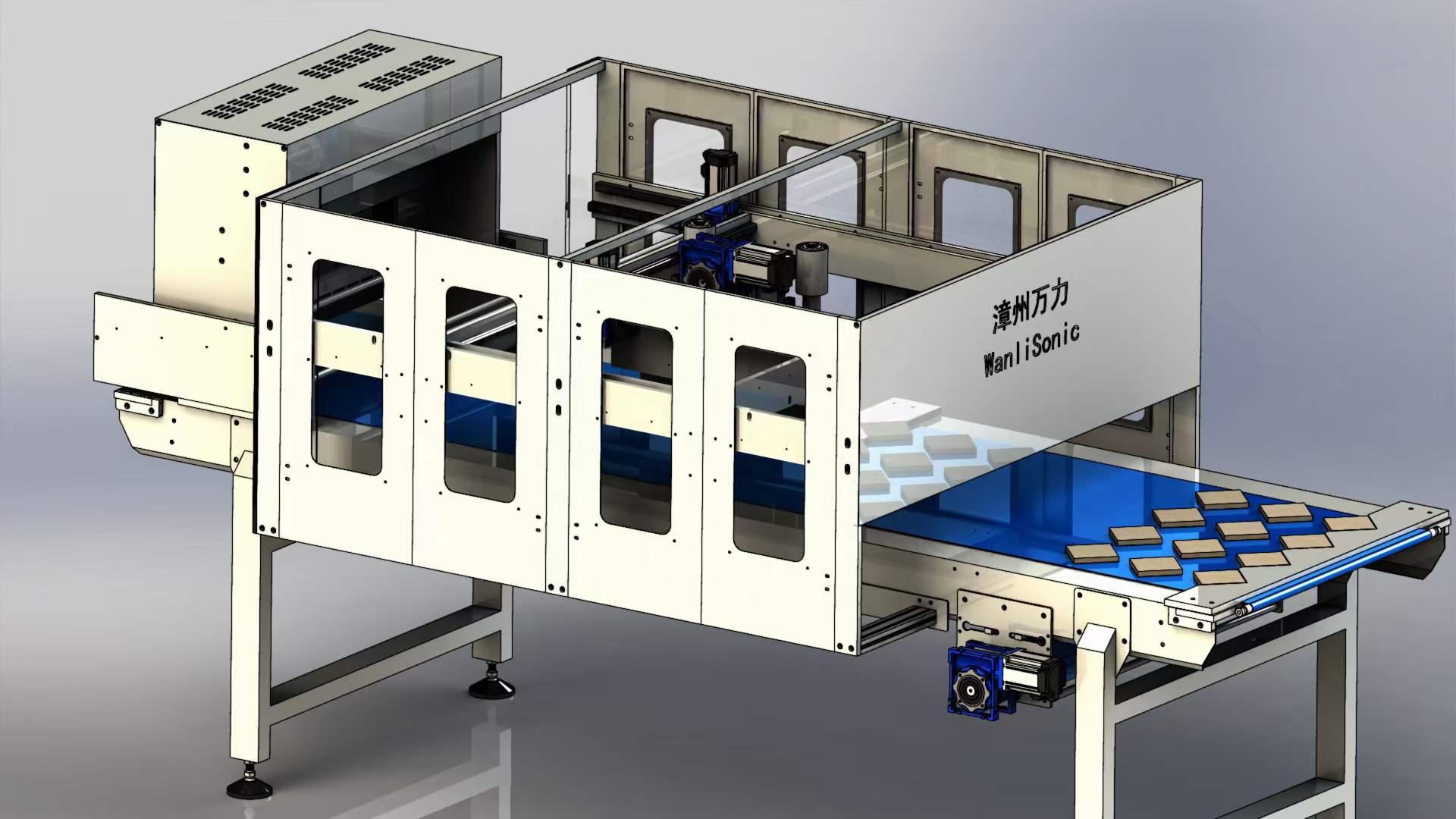

Components of an Ultrasonic Cutting Machine

An ultrasonic cutting machine comprises several key components: the ultrasonic generator, the transducer, and the cutting blade. Each plays a crucial role in ensuring the machine operates efficiently, delivering precise cuts every time.

Benefits of Using Ultrasonic Cutting Machines

Precision and Accuracy

One of the standout benefits of ultrasonic cutting machines is their precision. The high-frequency vibrations ensure clean, even cuts, reducing wastage and improving the aesthetic quality of the final product.

Efficiency and Speed

These machines are designed for speed. They can handle high volumes of food items quickly, making them ideal for commercial food production environments. This efficiency translates to lower operational costs and higher output.

Hygiene and Cleanliness

Ultrasonic cutting is inherently hygienic. The vibrations keep the blade cleaner, reducing the risk of contamination. This makes it an excellent choice for foods that are prone to sticking, like Swiss rolls and other pastries.

Features of Ultrasonic Swiss Roll Cutting Machines

Key Components and Their Functions

From the ultrasonic generator to the cutting blade, each component of the machine has a specific function. The generator produces the ultrasonic waves, the transducer converts these waves into mechanical vibrations, and the blade uses these vibrations to cut through the food.

Advanced Technologies Integrated

Modern ultrasonic cutting machines come equipped with advanced technologies like automated controls, adjustable settings, and real-time monitoring. These features ensure optimal performance and allow for customization based on specific cutting requirements.

Applications in the Food Industry

Swiss Rolls and Pastries

Swiss rolls are delicate, and cutting them without squashing or tearing can be challenging. Ultrasonic cutting machines ensure each slice is perfect, maintaining the integrity of the roll. These machines use high-frequency vibrations to make precise cuts without applying significant pressure, which is essential for keeping the structure and texture of Swiss rolls intact.

Precision in Pastry Cutting

Pastries often have intricate designs and delicate layers that require precise cutting. Traditional cutting methods can damage these delicate layers, leading to a loss of product quality and aesthetic appeal. Ultrasonic cutting technology addresses this issue by providing clean, sharp cuts that preserve the pastry’s integrity. This technology is particularly beneficial for high-volume production environments where consistency and efficiency are crucial.

Bread and Cakes

From artisanal breads to intricate cakes, ultrasonic cutters can handle a variety of baked goods, providing clean, precise cuts that enhance presentation and reduce waste. These machines are designed to cut through soft and delicate textures without causing any deformation or crumbling, which is crucial for maintaining the product’s appearance and texture.

Cheese and Other Soft Foods

Cheese, particularly soft varieties, can be tricky to cut. Ultrasonic machines make this task easy, producing smooth slices without crumbling or sticking. This method ensures that each slice of cheese maintains its shape and texture, which is essential for both presentation and consumer satisfaction.

Advantages of Ultrasonic Cutting Technology in the Food Industry

Enhancing Production Efficiency

Using ultrasonic cutting machines can significantly enhance production efficiency. These machines are designed to operate at high speeds while maintaining precision, allowing manufacturers to increase their output without compromising on quality. This efficiency is particularly important in the food industry, where demand for high-quality products is consistently high.

Improved Product Quality

One of the primary benefits of ultrasonic cutting technology is the improved quality of the final product. Traditional cutting methods can often cause deformation, crumbling, and uneven cuts, which negatively impact the product’s appearance and texture. Ultrasonic machines, on the other hand, provide clean, precise cuts that preserve the product’s integrity, resulting in a higher-quality end product.

Versatility in Application

Ultrasonic cutting technology is versatile and can be applied to a wide range of food products, including baked goods, confectionery items, and soft cheeses. This versatility makes it a valuable investment for food manufacturers looking to improve their production processes and product quality.

Reducing Waste

Traditional cutting methods often result in significant product waste due to uneven cuts and damage. Ultrasonic cutting machines minimize waste by providing consistent, precise cuts that maintain the product’s shape and texture. This reduction in waste not only improves production efficiency but also contributes to cost savings for manufacturers.

Enhancing Presentation

In the food industry, presentation is crucial. Products that look appealing are more likely to attract customers and drive sales. Ultrasonic cutting machines help enhance the presentation of food products by providing clean, uniform cuts that improve the overall appearance of the product. This benefit is particularly important for high-end and specialty food items where visual appeal is a key selling point.

Conclusion

Ultrasonic cutting technology offers significant advantages for the food industry, including improved product quality, increased production efficiency, and reduced waste. By using high-frequency vibrations to make precise cuts, these machines help maintain the integrity of delicate foods and enhance their presentation. As a result, food manufacturers can produce high-quality products that meet consumer expectations and drive business success.