Ultrasonic Swiss Roll Cutting Machine

In a groundbreaking advancement for the bakery and confectionery industries, the introduction of a multi-functional ultrasonic swiss roll cutting machine is set to redefine the standards of precision, efficiency, and hygiene. This state-of-the-art machine, designed to cut a variety of cakes including round cakes, square cakes, and swiss rolls, utilizes high-frequency ultrasonic waves to deliver clean, precise cuts while maintaining the integrity and aesthetic appeal of each dessert.

The Innovation Behind Ultrasonic Cutting Technology

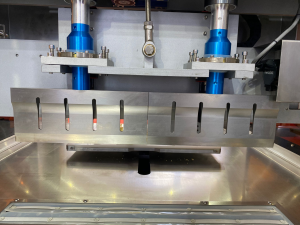

Ultrasonic cutting technology employs high-frequency vibrations transmitted through a blade, enabling it to slice through cakes with minimal resistance. This method not only ensures uniform and aesthetically pleasing cuts but also significantly reduces the production of crumbs and waste. The vibrations at a frequency typically between 20 and 40 kHz create a high-energy field at the cutting edge, allowing the blade to glide through delicate textures without causing deformation or smearing.

Versatility and Precision

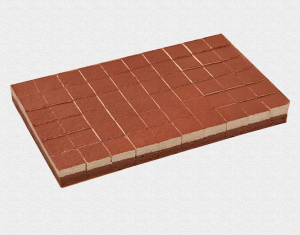

The ultrasonic swiss roll cutting machine is celebrated for its versatility. It can seamlessly handle round cakes, square cakes, and swiss rolls, making it an invaluable asset for bakeries and confectionery businesses. Whether cutting a dense chocolate cake, a fluffy sponge cake, or a delicate swiss roll, the machine consistently delivers precise and clean slices.

Round Cakes: The machine’s ability to cut round cakes with exact precision ensures each slice is identical, enhancing the visual appeal and portion control, crucial for commercial settings and special occasions.

Square Cakes: Cutting square cakes can be challenging due to the need for sharp, straight edges. The ultrasonic cutting machine excels in this area, providing perfectly straight cuts that maintain the cake’s structure and presentation.

Swiss Rolls: Swiss rolls, with their delicate layers and intricate designs, require exceptional precision in cutting. The ultrasonic machine’s gentle yet effective slicing action preserves the roll’s integrity and appearance, making it a preferred choice for high-end bakeries.

Enhanced Efficiency and Hygiene

One of the standout features of this ultrasonic swiss roll cutting machine is its blade self-cleaning mechanism. This automatic cleaning system ensures that the blade remains free from residue and buildup, which can compromise cutting performance and hygiene. The self-cleaning feature not only reduces downtime but also minimizes the need for manual cleaning, enhancing the overall efficiency of the production process.

Benefits for the Bakery Industry

The introduction of the ultrasonic swiss roll cutting machine brings numerous benefits to the bakery industry:

Precision and Consistency: The machine delivers precise and consistent cuts, ensuring uniformity in size and shape for each slice. This precision is crucial for maintaining the product’s visual appeal and portion control, particularly in commercial settings.

Time and Labor Efficiency: Automated operation and high cutting speed significantly reduce the time and labor required for cutting cakes. This efficiency allows bakery staff to focus on other important aspects of production, improving overall productivity.

Reduced Waste and Improved Yield: Clean, precise cuts result in less waste compared to traditional cutting methods. This improved yield translates to cost savings for businesses, as more of the product can be sold rather than discarded due to uneven or damaged pieces.

Enhanced Presentation and Quality: The smooth and clean cuts achieved with ultrasonic technology enhance the presentation and overall quality of cakes. This is particularly important for high-end bakeries and specialty shops where visual appeal is a key selling point.

Hygiene and Cleanliness: The blade self-cleaning feature ensures high standards of hygiene and cleanliness. By keeping the blade free of residue and buildup, this feature reduces the risk of contamination and makes the equipment easier to clean and sanitize.

Latest Innovations

Advanced Sensor Integration

Recent innovations in ultrasonic cutting machines include the integration of advanced sensors that monitor various parameters such as blade vibration, cutting speed, and product position. These sensors help to optimize the cutting process and ensure consistent results.

Automation and AI in Cutting

Automation and artificial intelligence are increasingly being incorporated into ultrasonic cutting machines. These technologies enable the machines to adapt to different products and cutting patterns automatically, reducing the need for manual adjustments and enhancing overall efficiency.

Improved Blade Coatings and Materials

Advancements in blade coatings and materials have led to the development of more durable and efficient cutting blades. These improvements enhance the machine’s performance, reduce wear and tear, and extend the lifespan of the blades.

Energy Efficiency Enhancements

Energy efficiency is a key focus in the development of modern ultrasonic cutting machines. New designs and technologies aim to reduce energy consumption while maintaining high cutting performance, making these machines more environmentally friendly and cost-effective to operate.

Compact and Mobile Units

The latest ultrasonic cutting machines are available in more compact and mobile units, making them suitable for small bakeries and on-site operations. These portable machines offer the same high-quality cutting performance as larger models but with added flexibility and convenience.

Looking to the Future

The future of the ultrasonic swiss roll cutting machine looks promising, with ongoing innovations set to enhance its capabilities and applications further:

Integration with 3D Printing: The potential integration of ultrasonic cutting machines with 3D printing technologies could enable the creation of highly customized and intricate designs, opening up new possibilities in the bakery and confectionery industries.

Customized Cutting Patterns: Future advancements are likely to include the ability to program and execute customized cutting patterns with greater ease, allowing businesses to offer a wider range of products and designs.

Conclusion

The ultrasonic swiss roll cutting machine represents a significant advancement in the bakery and confectionery industries, offering precision, efficiency, and enhanced product quality. With its ability to cut round cakes, square cakes, and swiss rolls, along with features like blade self-cleaning, this machine is poised to become an essential tool for modern bakeries. As technology continues to evolve, the capabilities of ultrasonic cutting machines will only expand, bringing even greater benefits to the food processing industry.