Products Previw:

This equipment is suitable for cake and bread food manufacturers and sandwich food manufacturers to inject fillings in the middle of cakes, breads and other products, such as liquid fillings such as jam, cream and salad, with accurate quantification and small error. It is an auxiliary equipment to increase the taste of products.

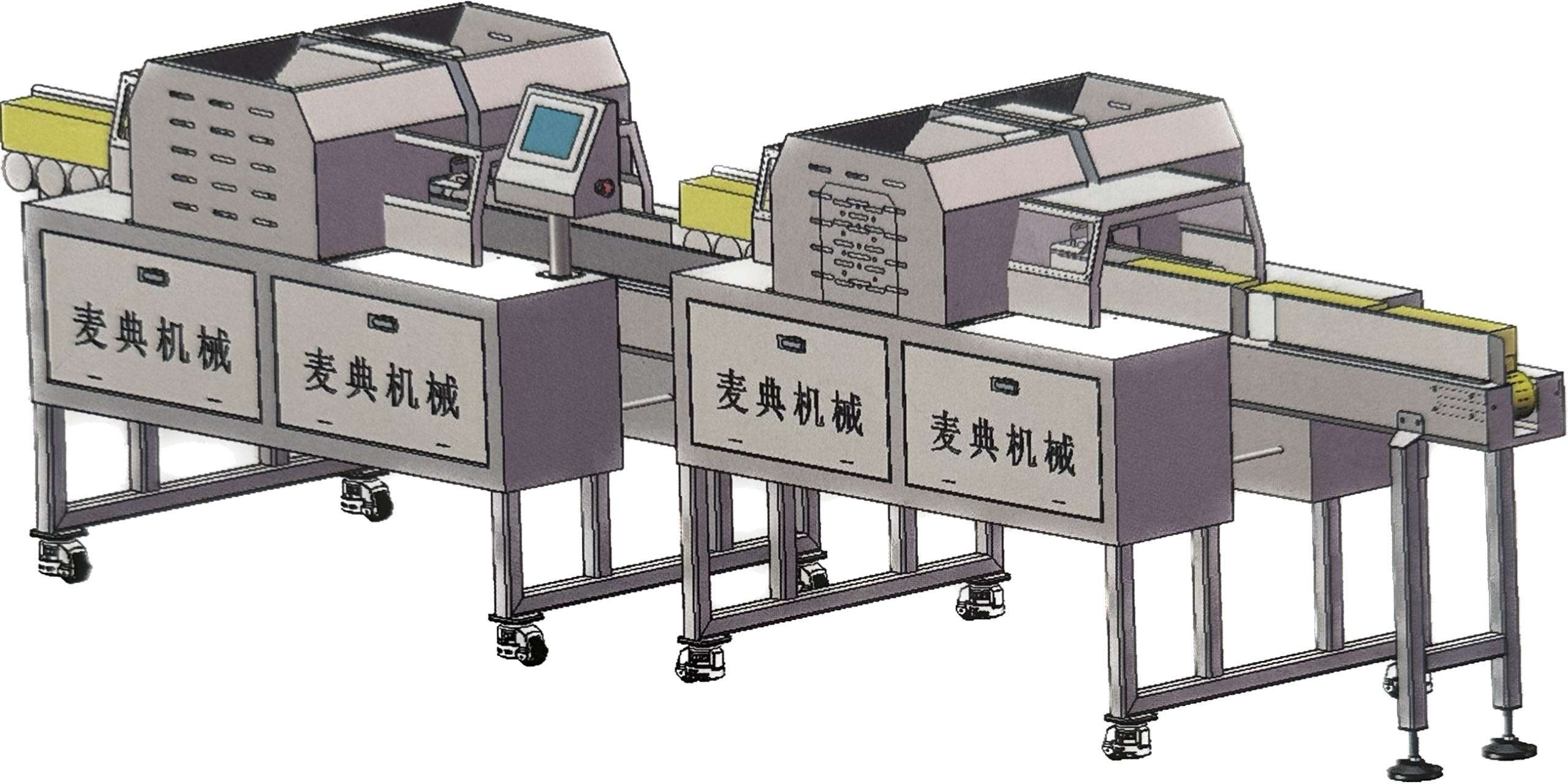

Components of a Sandwich Production Line

1.Toast Peeling Machine

Fully automatic toast peeling machine,capable of single or double peeling, and can be freely adjusted and cut according to the s ize of the product; lt can be peeled at high speed,with a flat incision and can cut 25 to 35 pieces per minute; Can match production lines according to customer needs; With storage function

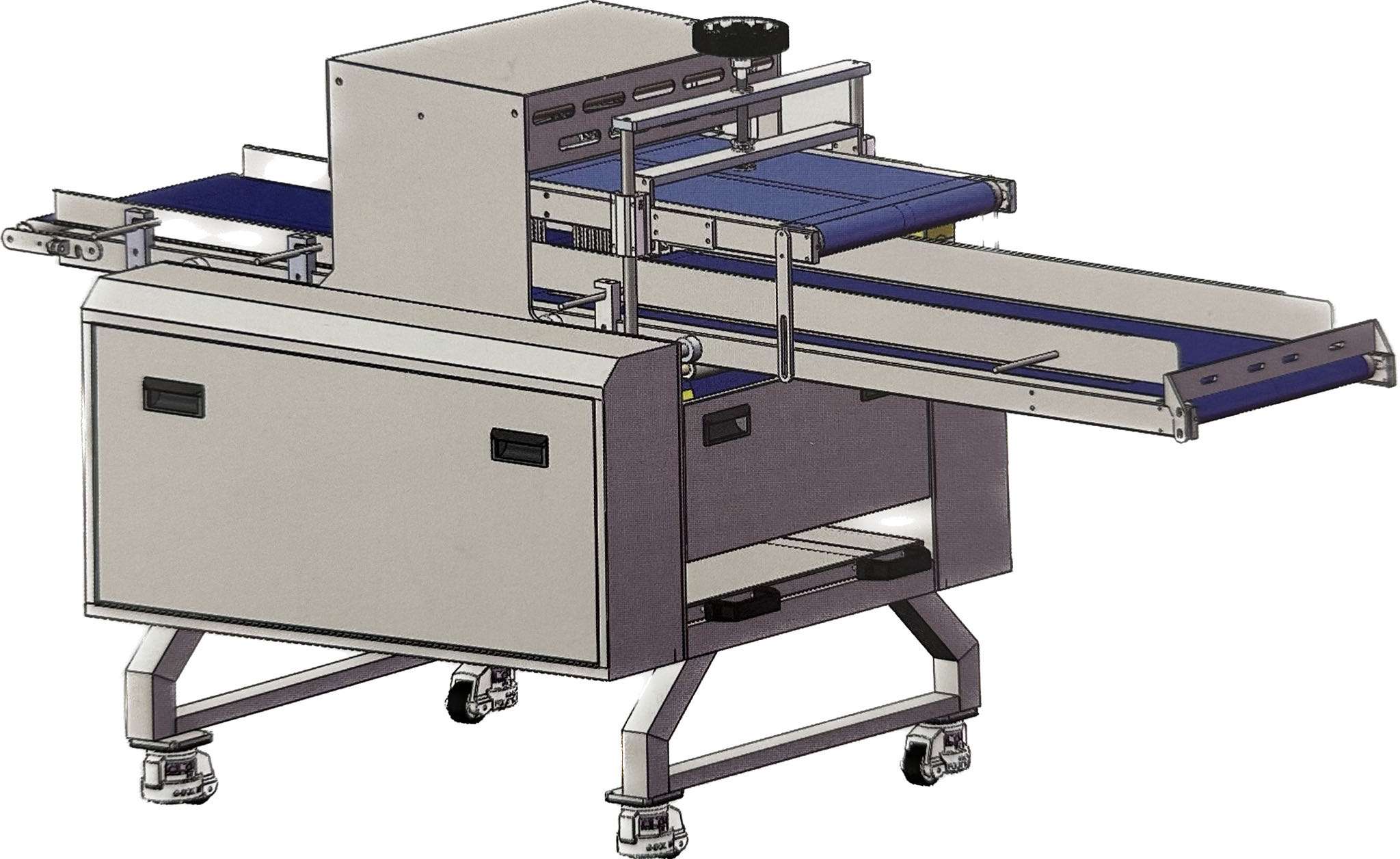

2.Bread Continuous Slicer

Mainly used as a multifunctional auxiliary equipment for bread manufacturers to continuously slice,slice, and block bread or toast. Multiple combinations can increase the appearance and specifications of bread and toast. The feeding method adopts a two-layer conveyor belt transportation method,which is stable, fast, and the product is smooth and flat without deformation. It can be suita ble for slicing bread and toast with varying degrees of softness and hardness.

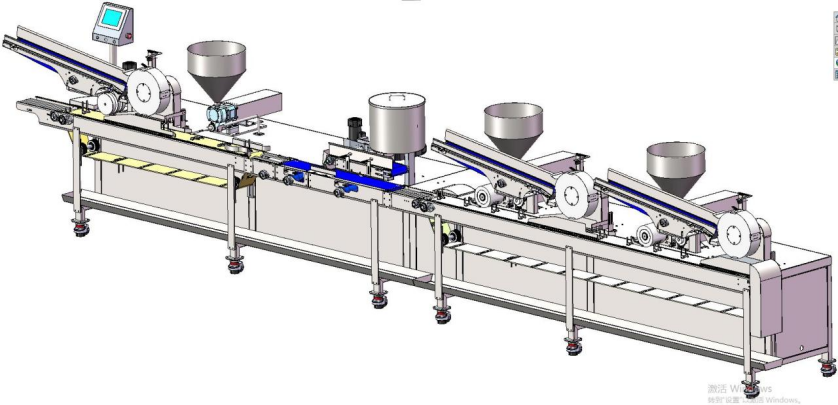

3.Cake And Bread Sandwich injection Machine

This device is suitable for cake and bread manufacturers to inject liquid fillings such as cream,jam,salad,etc. into products su ch as cakes,bread,and puffs. It has precise quantification and small error,and is also an auxiliary device to increase product taste.

4.Ultrasonic Cutting Machine

This equipment is mainly suitable for cake and bread manufacturers to perform ultrasonic cutting on cakes and bread. The cu t products are smooth and flat,and do not stick to the knife,without residue or debris.It is a substitute for traditional blade cutting.

Advantages

1. Increased Efficiency

Implementing a sandwich production line significantly increases efficiency in the production process. The automation of tasks reduces the need for manual labor, allowing businesses to produce sandwiches at a faster rate. This increased efficiency leads to higher productivity and cost savings in the long run.

2. Consistency in Quality

A sandwich production line ensures consistency in the quality of sandwiches produced. The use of machines and standardized processes eliminates human errors and variations, resulting in sandwiches that have the same appearance, taste, and texture. This consistency is crucial for building a strong brand reputation and satisfying customer expectations.

3. Cost Reduction

By automating the sandwich production process, businesses can reduce labor costs. Machines can perform tasks that would otherwise require multiple workers, allowing companies to allocate their human resources more efficiently. Additionally, the reduction in human errors and wastage leads to cost savings in terms of ingredients and materials.

4. Increased Production Capacity

A sandwich production line enables businesses to scale up their production capacity. With the automation of tasks, companies can produce a larger volume of sandwiches within a shorter timeframe. This increased production capacity allows businesses to meet the growing demands of their customers and expand their market reach.

Conclusion

A sandwich production line is a vital component of the food industry, enabling businesses to streamline their operations and deliver high-quality sandwiches efficiently. By understanding the various components and processes involved, companies can optimize their production processes, increase efficiency, and reduce costs.