Ultrasonic Layers Cake Cutting Machine

Introduction

Imagine a world where every slice of cake is perfect, with clean, smooth edges that make each piece look like it was cut by a master baker. This isn’t a fantasy—it’s the reality with ultrasonic layers cake cutting machines. These innovative devices have revolutionized the way cakes are sliced, offering precision, speed, and hygiene that traditional methods can’t match.

What is the Ultrasonic Layers Cake Cutting Machine?

An ultrasonic layers cake cutting machine is a specialized device designed to cut cakes using high-frequency ultrasonic vibrations. Unlike conventional knives, which rely on brute force to slice through cake layers, ultrasonic machines use a blade that vibrates at ultrasonic frequencies. This creates a smooth, clean cut with minimal crumbs and no smudging of icing or fillings.

Historical Development

The concept of using ultrasonic technology for cutting isn’t new. It originated in the industrial sector for cutting and welding materials like plastics and metals. However, its application in food processing, particularly in cake cutting, is a more recent innovation driven by the need for precision and efficiency in commercial baking.

How Does the Ultrasonic Layers Cake Cutting Machine Work?

Ultrasonic Technology Basics

Ultrasonic technology involves the use of high-frequency sound waves, typically above the range of human hearing (20 kHz). These sound waves are converted into mechanical vibrations by an ultrasonic transducer. When applied to a cutting blade, these vibrations create a rapid, high-frequency motion.

Detailed Working Mechanism

In an ultrasonic layers cake cutting machine, the ultrasonic generator produces high-frequency electrical energy, which is converted into mechanical vibrations by the transducer. These vibrations are transmitted to the cutting blade, which then vibrates at a frequency of 20,000 to 40,000 vibrations per second. This high-frequency motion allows the blade to glide through the cake with minimal resistance, resulting in a precise, clean cut.

Advantages of Using Ultrasonic Layers Cake Cutting Machine

Precision and Accuracy

One of the main benefits of ultrasonic cutting is its unparalleled precision. The vibrations reduce the friction between the blade and the cake, allowing for clean cuts that preserve the structure and appearance of each slice. This precision is especially crucial for intricate cake designs and multi-layered creations.

Speed and Efficiency

Ultrasonic machines can cut through cakes much faster than traditional methods. This increased speed doesn’t compromise the quality of the cut, making it ideal for high-volume production environments where time is of the essence.

Hygiene and Cleanliness

Because the ultrasonic blade vibrates so rapidly, it doesn’t collect residue as a regular knife would. This means less frequent cleaning is required, and the risk of cross-contamination is significantly reduced. It’s a more hygienic option, especially in commercial settings where maintaining cleanliness is critical.

Types of Ultrasonic Layers Cake Cutting Machines

Manual Machines

Manual ultrasonic cake cutters require the operator to handle the positioning and cutting process. They are typically used in smaller bakeries or specialty shops where production volumes are lower.

Semi-Automatic Machines

These machines combine manual handling with automated cutting processes. The operator positions the cake, and the machine takes over the cutting, offering a balance between manual control and automated efficiency.

Fully Automatic Machines

Fully automatic machines are designed for high-volume production lines. They handle everything from positioning the cake to executing precise cuts, requiring minimal human intervention.

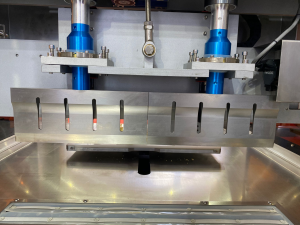

Key Components of Ultrasonic Layers Cake Cutting Machine

Ultrasonic Generator

The ultrasonic generator is the heart of the machine, producing the high-frequency electrical energy needed to create mechanical vibrations.

Self-cleaning Blade

The self-cleaning blade utilizes a unique combination of ultrasonic vibrations and a precisely engineered cleaning mechanism. As the blade cuts through layers of material, the vibrations create micro-turbulence at the cutting edge, effectively dislodging and removing any accumulated debris or residue. This process is continuous and automatic, ensuring that the blade remains clean and sharp throughout extended periods of operation.

Transducer

Converts the electrical signal into mechanical vibrations.

Applications of Ultrasonic Layers Cake Cutting Machine

Commercial Bakeries

In large commercial bakeries, ultrasonic machines streamline the slicing process, ensuring consistent, high-quality cuts that enhance the presentation and shelf life of cakes.

Specialty Cake Shops

For specialty cake shops, the precision of ultrasonic cutting is invaluable. It allows for intricate designs and delicate layers to be cut without damaging the overall structure of the cake.

Industrial Food Processing

In the industrial food processing sector, ultrasonic cutting machines are used for a variety of products beyond cakes, including cheesecakes, pies, and even frozen foods, demonstrating their versatility.

How to Choose the Right Ultrasonic Layers Cake Cutting Machine

Assessing Needs and Production Volume

When selecting an ultrasonic cake cutting machine, it’s essential to consider the production volume and specific needs of your operation. Smaller shops might benefit from manual or semi-automatic machines, while larger facilities will likely require fully automatic models.

Evaluating Features and Specifications

Look for features such as adjustable cutting speeds, blade frequencies, and ease of maintenance. A machine with customizable settings can adapt to different products and production requirements, offering greater versatility.

Future Trends in Ultrasonic Cake Cutting Technology

Innovations and Advancements

The future of ultrasonic cake cutting technology looks promising, with ongoing innovations aimed at improving efficiency, precision, and user-friendliness. Developments such as AI integration and enhanced automation are on the horizon.

Potential Improvements

Potential improvements include more energy-efficient designs, eco-friendly materials, and enhanced safety features, making these machines even more appealing to commercial and industrial users.

Conclusion

In conclusion, the Ultrasonic Layers Cake Cutting Machine represents a significant step forward in bakery production technology. Its precision cutting capabilities, smooth cutting surface, reduced waste, versatility, increased efficiency, and hygiene benefits make it an invaluable asset for bakeries looking to elevate their products, streamline their operations, and stay ahead of the competition. As the industry continues to embrace this innovative technology, the future of bakery production looks brighter than ever.