Ultrasonic Cake Cutting Machine

The baking industry has seen significant technological advancements over the years, from simple hand tools to automated production lines. Among these innovations, the ultrasonic cake cutting machine stands out as a game-changer. This cutting-edge technology not only enhances the precision and speed of cake slicing but also integrates seamlessly into modern production lines, making it a must-have for both industrial and boutique bakeries.

Ultrasonic Cutting Technology

What is Ultrasonic Cutting?

Ultrasonic cutting is a process that utilizes high-frequency sound waves to vibrate a cutting blade. These vibrations create an almost frictionless surface, allowing the blade to glide through various materials, including soft and delicate cakes, with minimal resistance.

How Ultrasonic Cutting Works

Ultrasonic cutting works by generating high-frequency sound waves, these sound waves cause the blade to vibrate at an incredibly high speed, enabling it to cut through cakes cleanly and efficiently. The vibrations also prevent sticking, ensuring that each slice is as clean as the last.

Advantages of Ultrasonic Cutting Over Traditional Methods

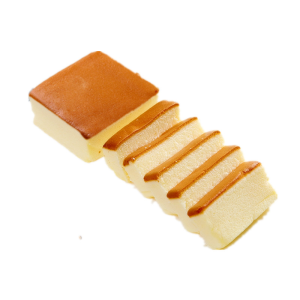

Compared to traditional cutting methods, ultrasonic cutting offers numerous advantages. It reduces the risk of product deformation, minimizes waste, and ensures consistent slice thickness. Additionally, it is capable of handling a wide variety of cake types, from dense cheesecakes to airy sponge cakes.

The Importance of Precision in Cake Cutting

Challenges of Traditional Cake Cutting

Traditional cake cutting methods often result in uneven slices, crumbled edges, and product waste. These issues are particularly problematic in high-volume production environments, where consistency is crucial for maintaining product quality and customer satisfaction.

The Role of Technology in Achieving Precision

Precision is key in the baking industry, especially when it comes to slicing cakes. Ultrasonic cutting technology provides the accuracy needed to produce uniform slices every time, regardless of the cake’s texture or composition.

Case Studies of Precision in Baking

Numerous bakeries have reported significant improvements in product quality after switching to ultrasonic cutting machines. For example, one industrial bakery saw a 20% reduction in waste and a 30% increase in production efficiency after implementing this technology.

Features of the Ultrasonic Cake Cutting Machine

Blade Composition and Design

The blade of an ultrasonic cake cutting machine is typically made from titanium or other durable materials that can withstand high-frequency vibrations. The design of the blade is crucial, as it must be sharp enough to cut through dense cakes yet gentle enough to slice through delicate layers without causing damage.

Conveyor Belt Integration

One of the standout features of the ultrasonic cake cutting machine is its ability to integrate with conveyor belts. This integration allows for continuous, automated slicing, which is ideal for large-scale production environments. Cakes can be placed on the conveyor belt, sliced, and then moved down the line for further processing or packaging.

Connectivity with Production Lines

Modern ultrasonic cake cutting machines are designed to connect seamlessly with existing production lines. This connectivity ensures that the cutting process is synchronized with other stages of production, from baking to packaging, thereby streamlining operations and reducing downtime.

Benefits of Using an Ultrasonic Cake Cutting Machine

Enhanced Efficiency and Speed

One of the primary benefits of using an ultrasonic cake cutting machine is the increase in efficiency and speed. The machine can slice through cakes much faster than manual methods, allowing bakeries to meet higher production demands without sacrificing quality.

Consistency in Cake Slices

Consistency is critical in the baking industry, and ultrasonic cutting machines excel in this area. Each slice is uniform in size and shape, ensuring that every piece looks as good as it tastes. This consistency is especially important for products sold in retail environments, where appearance can significantly impact customer purchasing decisions.

Minimizing Waste and Maximizing Yield

Ultrasonic cutting minimizes waste by producing clean, precise cuts that reduce the amount of product discarded due to imperfections. This not only increases yield but also contributes to cost savings over time.

Versatility Across Different Cake Types

Whether it’s a dense chocolate cake, a light sponge, or a multi-layered creation, an ultrasonic cake cutting machine can handle it all. Its versatility makes it a valuable tool for bakeries that produce a wide range of products, ensuring that each one is sliced to perfection.

Applications in Various Sectors

Industrial Baking

In large-scale industrial baking, where thousands of cakes are produced daily, the ultrasonic cake cutting machine proves invaluable. Its ability to work continuously without losing precision makes it ideal for high-volume operations.

Artisan and Boutique Bakeries

For smaller, artisan bakeries, the ultrasonic cake cutting machine offers the same level of precision but on a scale that suits their needs. These bakeries can benefit from the machine’s ability to produce beautifully sliced cakes that enhance their handcrafted appeal.

Catering and Event Services

In the catering industry, presentation is everything. Ultrasonic cake cutting machines ensure that cakes served at events are sliced perfectly, adding to the overall aesthetic and quality of the food presentation.

Implementation and Maintenance

Integrating the Machine into Existing Production Lines

Integrating an ultrasonic cake cutting machine into an existing production line is straightforward, thanks to its modular design. Most machines come with customizable settings that allow them to fit seamlessly into various stages of production.

Routine Maintenance Tips

Regular maintenance is key to keeping the ultrasonic cake cutting machine in optimal condition. This includes cleaning the blade after each use, checking for wear and tear, and ensuring that all components are functioning correctly.

Troubleshooting Common Issues

While ultrasonic cake cutting machines are generally reliable, occasional issues may arise. Common problems include blade dulling or misalignment, which can usually be resolved with routine maintenance or minor adjustments.

Future Trends in Ultrasonic Cutting Technology

Innovations on the Horizon

The future of ultrasonic cutting technology looks promising, with ongoing innovations aimed at improving efficiency, precision, and versatility. Upcoming developments may include enhanced automation features and more energy-efficient designs.

Potential Impact on the Baking Industry

As ultrasonic cutting technology continues to evolve, its impact on the baking industry is expected to grow. This technology will likely become a standard feature in modern bakeries, helping businesses stay competitive by offering superior product quality and operational efficiency.

Conclusion

The ultrasonic cake cutting machine is more than just a tool—it’s a revolution in the baking industry. With its ability to deliver precise, consistent slices quickly and efficiently, this machine is set to become an essential part of both industrial and artisan bakeries. As technology advances, the possibilities for ultrasonic cutting in the baking industry are limitless, promising a future where perfection is the standard, not the exception.

FAQs

What types of cakes can be cut using an ultrasonic cake cutting machine?

Ultrasonic cake cutting machines can handle a wide variety of cakes, from dense cheesecakes to light sponge cakes and multi-layered creations.

How does ultrasonic cutting prevent damage to delicate cakes?

The high-frequency vibrations of the ultrasonic blade create a nearly frictionless cutting surface, which reduces the risk of tearing.