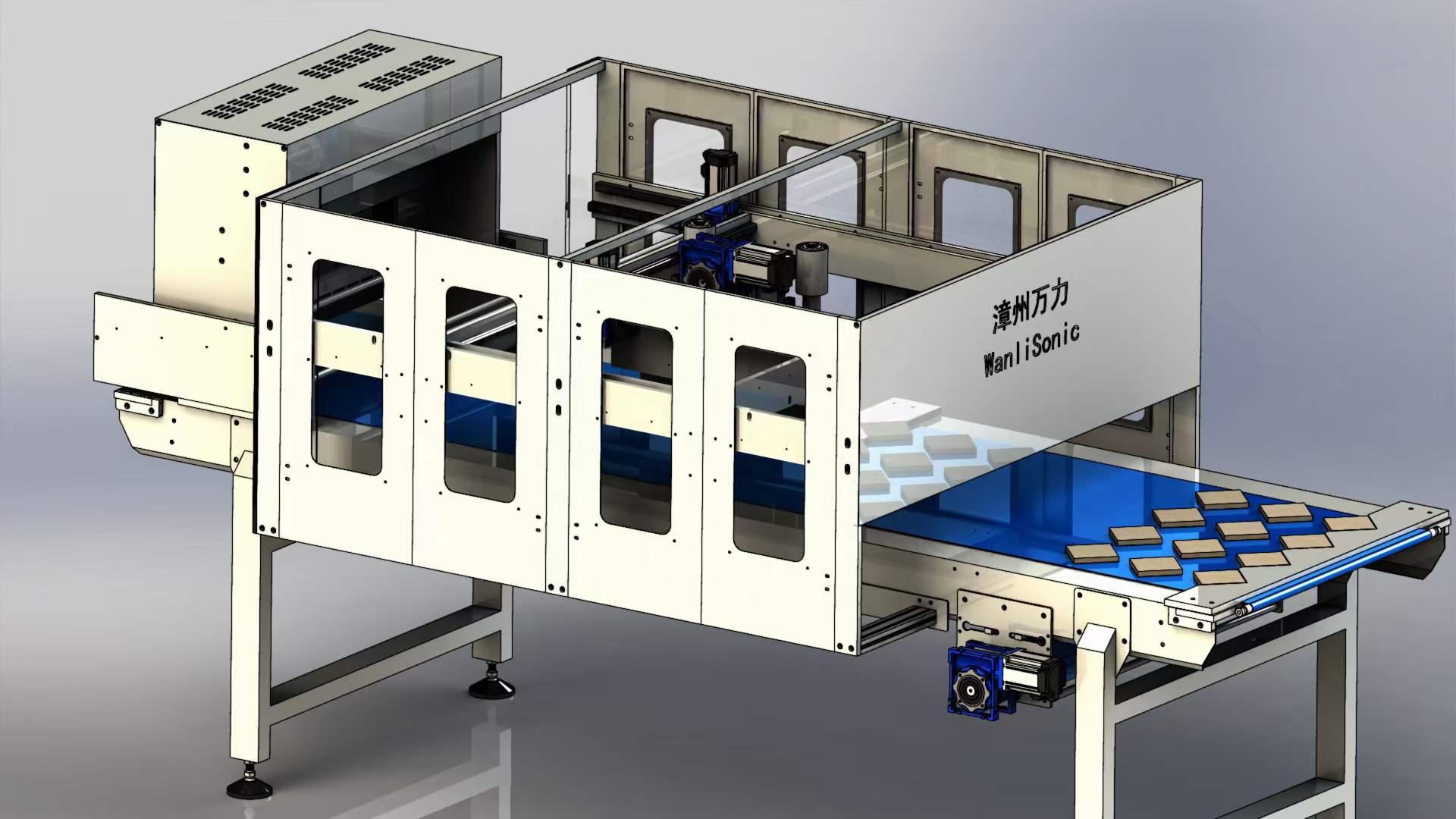

Ultrasonic Licorice Candy Cutting Machine

In the vast and ever-evolving world of confectionery, innovation is the key to staying ahead. Traditional methods of candy production, while nostalgic and often beloved, can be inefficient and inconsistent in terms of quality and output. One area where technology has made a significant impact is in the cutting and shaping of candies, particularly licorice. Introducing the ultrasonic licorice candy cutting machine, a game-changer that combines precision, efficiency, and reliability to elevate the production of licorice candies to new heights. This blog post will delve into the intricacies of this remarkable machinery, exploring its workings, benefits, and the transformative impact it has had on the sweet confectionery industry.

Introduction: The Need for Innovation in Candy Production

Candy production has long been a labor-intensive process, with manual cutting and shaping methods dominant in many parts of the world. Licorice, known for its flexible yet chewy texture, poses unique challenges in manufacturing. Traditional methods often involve the use of knives or blades to cut the licorice into desired shapes and sizes, a process that can be time-consuming, labor-intensive, and prone to inconsistencies. Furthermore, manual cutting can lead to variations in size and shape, affecting both the aesthetic appeal and consumer experience.

As consumer demands for higher quality, more consistent products increase, the need for innovation in candy production becomes paramount. Manufacturers are continually seeking ways to enhance productivity, reduce waste, and improve product uniformity. Enter the ultrasonic licorice candy cutting machine—a technological marvel that addresses these challenges head-on.

The Mechanics Behind Ultrasonic Cutting Technology

Ultrasonic technology leverages high-frequency vibrations to perform precise cutting actions. In the context of licorice candy cutting, this technology involves the use of an ultrasonic transducer that converts electrical energy into mechanical vibrations. These vibrations are then transmitted through a tool tip, typically a blade or horn, which contacts the licorice material.

The key advantage of ultrasonic cutting lies in its non-contact nature and the precision it offers. Unlike traditional blades that rely on physical pressure to cut through material, ultrasonic blades use the energy of the vibrations to create friction and heat at the point of contact. This results in a cleaner, more precise cut with minimal stress on the material. The high-frequency vibrations also allow for the cutting of intricate shapes and patterns with remarkable accuracy, ensuring uniformity in size and shape.

Moreover, ultrasonic cutting is highly adaptable. The frequency and amplitude of the vibrations can be adjusted to suit different types of licorice formulations, textures, and desired cut specifications. This flexibility makes the ultrasonic cutting machine a versatile tool for manufacturers working with a wide range of licorice products.

Benefits of Using an Ultrasonic Licorice Candy Cutting Machine

-

Precision and Uniformity: As mentioned, the high-frequency vibrations ensure a clean, precise cut, resulting in licorice candies of uniform size and shape. This consistency enhances the overall aesthetic appeal of the product and meets the expectations of discerning consumers.

-

Increased Efficiency: Ultrasonic cutting is significantly faster than manual methods, enabling manufacturers to increase production volumes without compromising on quality. This boost in efficiency translates to cost savings and a competitive edge in the market.

-

Reduced Waste: The precision of ultrasonic cutting minimizes material waste. With less scrap and rejects, manufacturers can optimize their raw material usage, further enhancing profitability.

-

Versatility: The ability to adjust the frequency and amplitude of vibrations makes the ultrasonic cutting machine suitable for a variety of licorice formulations and textures. This versatility allows manufacturers to easily switch between different products, reducing the need for specialized equipment.

-

Improved Safety: Ultrasonic cutting eliminates the need for sharp blades that can pose a risk to operators. The non-contact nature of the technology reduces the likelihood of accidents, creating a safer work environment.

-

Sustainability: By reducing waste and increasing efficiency, ultrasonic cutting machines contribute to more sustainable production practices. Manufacturers can reduce their carbon footprint and align their operations with the growing trend of eco-friendly confectionery.

Conclusion: The Future of Candy Production with Ultrasonic Technology

The ultrasonic licorice candy cutting machine represents a pivotal shift in the confectionery industry, blending advanced technology with traditional craftsmanship to deliver superior results. By offering precision, efficiency, and versatility, this machinery has set a new benchmark for candy production.

As consumer demands continue to evolve, manufacturers must adapt to stay competitive. The ultrasonic licorice candy cutting machine is not just a tool; it is a catalyst for innovation and growth. It enables manufacturers to produce higher quality, more consistent licorice candies while optimizing their production processes and enhancing safety.

In summary, the ultrasonic licorice candy cutting machine is a testament to the power of technology in transforming traditional industries. It is a game-changer that has reshaped the landscape of candy production, setting the stage for a brighter, more sustainable future in the sweet confectionery world. As manufacturers continue to explore the potential of ultrasonic technology, the possibilities for innovation and improvement are limitless.