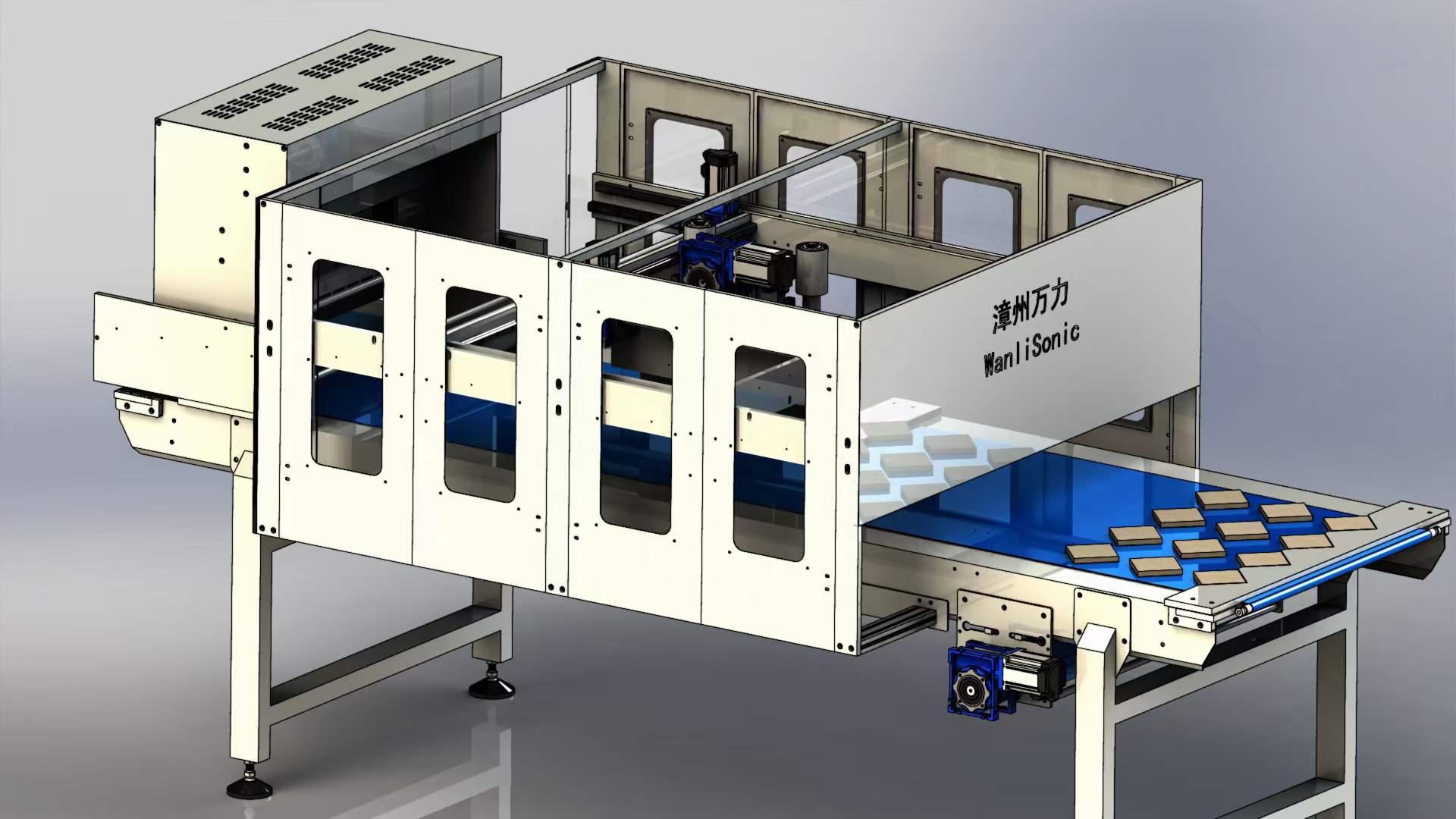

Ultrasonic Brownie Cutting Machine

In the realm of culinary arts, innovation often stems from the most unexpected places. While traditional techniques have stood the test of time, technological advancements are continuously shaping the way we prepare, present, and enjoy our favorite treats. One such groundbreaking innovation is the ultrasonic brownie cutting machine—a device that’s not only redefining the art of brownie cutting but also setting new standards for precision, efficiency, and hygiene in baking. This news post delves into the fascinating world of ultrasonic technology in the kitchen, focusing specifically on how this machine is transforming the lives of bakers and pastry chefs.

Introduction: The Concept and Necessity of Ultrasonic Technology in Baking

Ultrasonic technology, traditionally known for its applications in fields like medical imaging, cleaning, and welding, might seem an unlikely candidate for the culinary world. However, its adaptability and versatility have led to its incorporation into various food processing tasks, including cutting, mixing, and even tenderizing meat. The principle behind ultrasonic cutting involves the use of high-frequency vibrations—typically between 20 kHz to 40 kHz—to create friction and heat at the point of contact, enabling precise and clean cuts without the need for traditional blades.

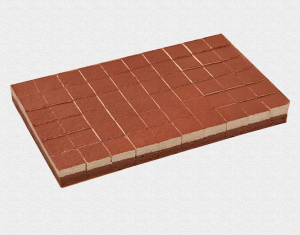

In the context of baking, especially when dealing with delicate and sticky items like brownies, traditional cutting methods can often lead to uneven slices, crushed edges, and even contamination risks from metal blades. The ultrasonic brownie cutting machine addresses these challenges by offering a non-contact, vibration-based solution that ensures every slice is perfect, preserving the integrity of the baked goods while enhancing overall presentation.

Body: The Benefits and Workings of the Ultrasonic Brownie Cutting Machine

- Precision and Uniformity

Precision and Uniformity: The most significant advantage of ultrasonic cutting is its ability to produce uniformly shaped brownie slices. The vibrations ensure that the blade glides smoothly through the brownie, reducing the risk of crumbling and ensuring every slice is a perfect rectangle. This is particularly beneficial for bakeries and cafes that prioritize visual appeal and customer satisfaction. With every brownie slice looking identical, customers are more likely to be impressed, leading to increased satisfaction and repeat business.

- Hygiene and Food Safety

Food safety is paramount in any food service environment. Traditional cutting tools can harbor bacteria, especially if not properly cleaned and maintained. The ultrasonic brownie cutting machine, however, minimizes this risk due to its non-contact design. There are no blades to rust, harbor contaminants, or require frequent sharpening. Instead, the vibrations create a gap between the tool and the brownie, reducing the likelihood of cross-contamination. Additionally, many models come with easy-to-clean surfaces and can be sanitized efficiently, adhering to strict hygiene standards.

- Efficiency and Speed

In a fast-paced kitchen, time is a precious commodity. The ultrasonic brownie cutting machine significantly cuts down the time required for slicing, allowing bakers to handle larger batches more efficiently. The machine operates swiftly, producing dozens of perfect slices in a fraction of the time it would take using manual methods. This increased speed not only boosts productivity but also leaves more time for other tasks, such as decorating or preparing additional dishes.

- Reduced Waste and Cost Savings

Traditional cutting methods often result in uneven slices, leading to waste, especially when the edges are too crumbled to serve. With the ultrasonic brownie cutting machine, every piece is usable, minimizing waste and maximizing profit. Moreover, the long-term cost savings associated with reduced blade replacement and maintenance further sweeten the deal for bakery owners.

- Versatility and Applicability

While designed primarily for brownies, the ultrasonic cutting principle can be adapted for other types of baked goods, including cakes, cheesecakes, and even bars. Its versatility makes it a valuable addition to any pastry chef’s arsenal, allowing for consistent results across a wide range of products. This adaptability ensures that the machine remains a relevant and useful investment, even as menu offerings evolve.

Conclusion: Embracing the Future of Baking with Ultrasonic Technology

In conclusion, the Ultrasonic Brownie Cutting Machine represents a significant leap forward in baking technology, combining precision, hygiene, efficiency, and versatility in a single, innovative package. It’s not just a tool; it’s a testament to the power of combining tradition with modern science to create something truly remarkable. As the culinary world continues to evolve, we can expect more such innovations to emerge, each designed to make our culinary endeavors easier, safer, and more enjoyable.

For bakers and pastry chefs, embracing ultrasonic technology is not just about staying ahead of the curve; it’s about delivering an unparalleled experience to your customers, one that is rooted in precision and crafted with care. The Ultrasonic Brownie Cutting Machine is just the beginning of a new chapter in baking, one where technology and tradition work hand in hand to create delicious memories, one slice at a time.